Capacitors are a big deal in power conversion systems. They grab and let go of energy, keeping circuits running nice and smooth. In a buck converter, capacitors hold voltage steady and knock out bumps caused by quick switching. This even keel is super important for making gadgets work well and last for ages.

They also clear out annoying noise and ripples in the power supply. By smoothing voltage, capacitors keep delicate parts from getting scrambled. How good they are at this depends on their knack for handling changing currents without wearing out.

The current rushing through a capacitor in a buck converter really shapes how it performs and how long it hangs in there. As the converter switches, the capacitor fills up and empties out fast. These speedy cycles create ripple currents, which can heat things up and cause problems if not managed right.

Ripple current is a huge thing because it brings on heat stress. Too much heat can toast the capacitor, cut its life short, and maybe even mess up nearby parts. Choosing a capacitor that can tackle strong ripple currents and has low equivalent series resistance (ESR) is key for killer performance.

A buck converter has a handful of main pieces: an input capacitor, an output capacitor, an inductor, a switch (often a transistor), and a diode or synchronous rectifier. The input capacitor tames voltage ripples from the power source. The output capacitor, meanwhile, keeps the voltage smooth for the device.

How these bits team up decides how well the converter deals with the capacitor current. For example, when the switch turns on, energy gets stored in the inductor while also juicing up the output capacitor. When the switch turns off, the inductor lets out energy to keep the current flowing steadily to the device. This push-and-pull puts a heap of stress on both capacitors.

Switching speed plays a massive role in how capacitor current acts. Faster switching often means you can use smaller inductors and capacitors, but it jacks up ripple current through them. This trade-off needs some clever planning during design.

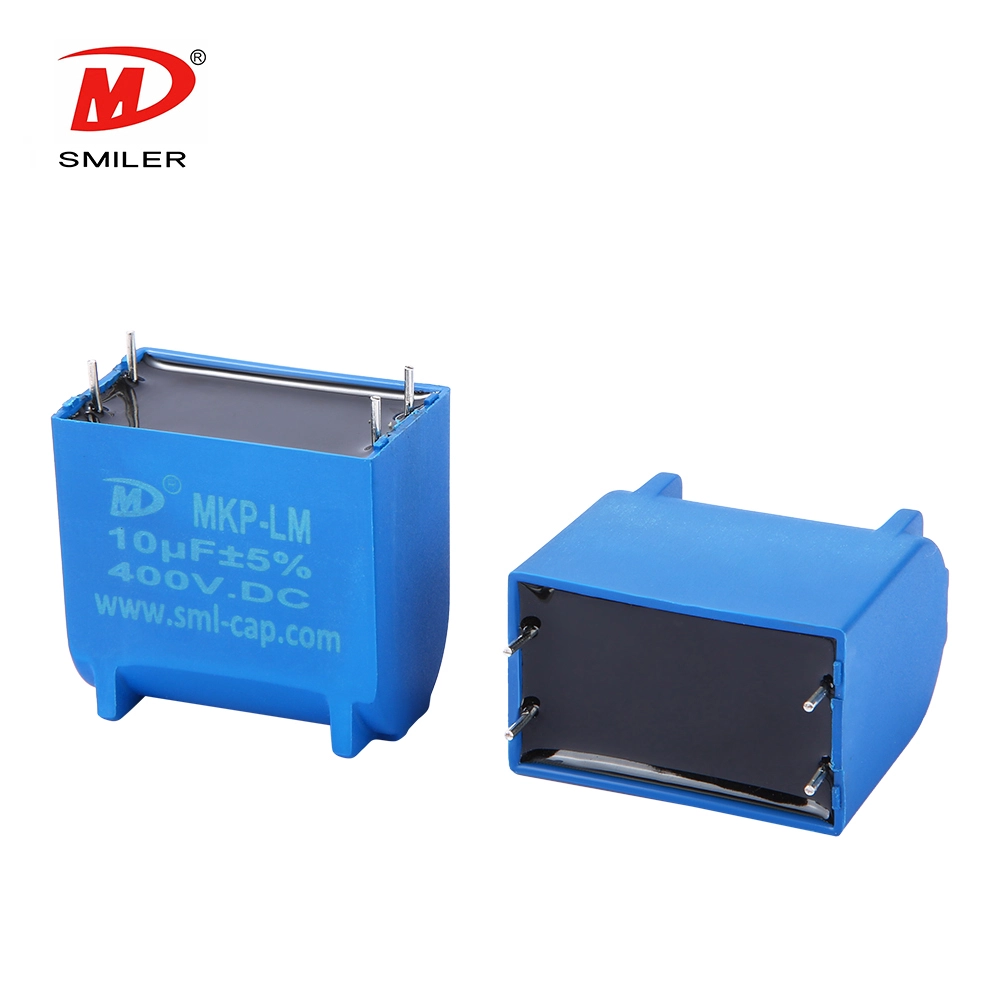

For instance, at high speeds, capacitors with low ESR are the best bet since they can handle ripple currents without getting too hot. Capacitors like DC Link MKP-LM are made for high-speed tasks, offering solid overcurrent strength and a long life. Picking the right capacitor ensures it can take the heat while staying reliable.

One big headache is handling heat from ripple currents. As we mentioned, too much heat can wear down capacitor materials over time. Another issue is making sure capacitors play nice with other parts like inductors and switches.

High switching speeds make things trickier by pumping up ripple current levels. Plus, stuff like temperature swings can throw off how capacitors work. For example, capacitors running above 85°C might need some tweaks to stay solid.

Another pain is cutting down stray inductance in circuit layouts. Stray inductance can spark voltage spikes during switching, which puts extra strain on capacitors and other parts

.

Here are some practical ways to fix these issues:  1.Picking Top-Notch Capacitors: Go for capacitors with low ESR to keep heat from ripple currents low.

1.Picking Top-Notch Capacitors: Go for capacitors with low ESR to keep heat from ripple currents low.

2. Tuning Up Circuit Layout: Place capacitors near power switches to cut stray inductance.

3. Using a Bunch of Capacitors: Spread current across several capacitors to lighten the load on each one.

4. Choosing Cool Materials: Metallized polypropylene film capacitors are tough and can patch up small faults by themselves.

5. Getting the Speed Right: Set a switching speed that keeps things efficient without overloading parts.

By thinking about these steps when designing and setting up, engineers can make systems run better and last longer.

SMILER's buck converter capacitors are built for fantastic results and trustworthiness in all sorts of setups. They use high-quality materials like metalized polypropylene film, which delivers great performance. Their self-healing feature lets them bounce back from tiny electrical glitches, helping them last a lot longer. Plus, their low ESR keeps energy waste and heat down, making them perfect for fast-switching systems.

Their tough build makes them super reliable. They've got resin-filled potting inside, which is great at resisting flames and keeping things safe even in harsh spots. Also, their ability to handle big ripple currents without falling apart makes them a top pick for heavy-duty power setups.

One neat thing about SMILER's capacitors is how they fit into different power setups. They're made to work smoothly across a wide range of voltages and temperatures. For example, they can handle temps from -40°C to +105°C, with some tweaks above 85°C to keep things running smoothly.

Their high voltage ratings, from 500VDC to 1200VDC, make them ideal for systems needing strong insulation and steadiness. This flexibility means they slide right into setups like industrial power supplies, car DC-DC converters, and green energy projects.

SMILER's capacitors stand out in tons of areas because of their awesome performance. Frequency converters and high-end industrial power supplies, keep voltage steady and cut down on noise. Their knack for handling high overvoltage and overcurrent makes them essential in these setups.

In cars, especially in DC-DC converters and electric vehicle (EV) charging systems, these capacitors help manage energy smartly. They support fast charging by handling big ripple currents and staying steady under changing demands.

On top of that, SMILER's capacitors are a big win in solar inverters. They boost the efficiency of solar power systems by leveling out voltage changes caused by shifting sunlight. This keeps power output nice and steady.

Q: What's the job of a buck converter's output capacitor?

A: It smooths out voltage jumps from switching, giving steady power to connected gadgets.

Q: Why is low ESR such a big deal for buck converter capacitors?

A: Low ESR keeps heat from ripple currents low, making things more stable and helping capacitors last longer.

Q: How does switching speed affect picking a capacitor?

A: Faster speeds need capacitors that can handle bigger ripple currents to avoid getting too hot or breaking down.

Q: What should I think about when choosing a capacitor for a buck converter?

A: Look at voltage rating, capacitance, ESR, ripple current strength, and temperature range.

Q: Are there materials that make capacitors more reliable?

A: Yup, things like metalized polypropylene film boost reliability with self-healing and strong insulation.