Capacitors are super important in DC circuits because they store and release energy, keep voltage steady, and zap unwanted noise. They act like little energy tanks, holding a charge when hooked to power and letting it out when needed. This trick is key to keeping circuits running smoothly, especially where stable voltage is a big deal.

In DC setups, capacitors often block out pesky signals. They let AC signals slip through while stopping DC, which cuts down on noise and keeps the circuit humming without hiccups. Plus, they shield delicate parts by soaking up voltage spikes that pop up during switching or other sudden changes.

Capacitors do a great job keeping voltage and current steady in DC circuits. When the load or power input shifts suddenly, capacitors release stored energy to keep voltage even. This buffering stops sharp drops or spikes that could mess up electronic parts.

Ripple current, the AC wiggle riding on the DC signal is another thing capacitors handle well. They smooth out these ripples for cleaner current flow, which is crucial for things like motor drives, LED lights, and power supplies. Ripple current can heat up a capacitor, though. Too much heat can push it past its maximum temperature and wreck it fast. Capacitors with low Equivalent Series Resistance (ESR) are awesome at managing high ripple currents without getting too hot.

Picking the perfect capacitor for DC circuits depends on a few key things:

1. Capacitance Value: This decides how much charge the capacitor can hold. Bigger values are great for jobs needing lots of energy storage.

2. Voltage Rating: The capacitor's voltage rating needs to be higher than the circuit's to avoid breakdowns.

3. ESR (Equivalent Series Resistance): Lower ESR means less power waste, making the circuit more efficient.

4. Material Type: Different materials bring different perks. For example, metalized polypropylene film capacitors have low ESR, handle high ripple currents, fix small faults on their own, and last a long time.

5. Temperature Range: A wide temperature range keeps performance steady in all kinds of environments.

Using capacitors in DC circuits can bring some headaches, like:

1. Leakage Current: All capacitors leak a bit of current over time because their insulating material isn't perfect. Too much leakage can waste energy and lower efficiency.

2. Aging: High heat or heavy ripple currents can age capacitors faster, cutting their lifespan short.

3. Polarization Issues: Electrolytic capacitors need the right polarity. Flipping it can cause overheating or even make it burst. They can handle a reverse voltage of 1.5V, but anything more will damage them.

The capacitance value has a big impact on how well a circuit handles changes in load or power supply. Here's the deal:

1. Bigger capacitance stores more energy but can make the capacitor larger and pricier.

2. Smaller capacitance might not cut it for jobs needing strong buffering against voltage swings.

Picking the right capacitance keeps the circuit running smoothly without going overboard. It also helps cut internal resistance, lower leakage current, reduce losses, and make the capacitor last longer. The rated surge voltage matters too—it shows how much extra voltage the capacitor can take without breaking. Choosing the right ratings lowers the risks of sudden spikes.

Where you put a capacitor in a DC circuit makes a huge difference:

1. Decoupling Jobs: Stick decoupling capacitors close to integrated circuits to zap high-frequency noise.

2. Power Supply Stability: Place bulk capacitors near power sources to keep voltage steady across the system.

3. Cutting Inductance Effects: Keep capacitors near their load to reduce stray inductance, which can cause voltage spikes that hurt power devices.

A smart layout also spreads heat evenly around sensitive parts, avoiding hot spots from nearby components. Getting this right boosts how well the capacitor does its job.

SMILER's DC capacitors are built tough to meet the demands of modern DC circuits. Their smart design and top performance make them a great fit for jobs needing reliability, efficiency, and long life. Their high-tech production lines crank out capacitors with precision and consistency, hitting a quality rate above 99.93%. That means you can count on them to work great every time.

SMILER's DC capacitors come with some cool features that make them shine:

1. Low ESR: Low ESR cuts down on power waste, keeping energy transfer smooth. This is a big win for circuits with high ripple currents.

2. High Ripple Current Handling: These capacitors can take on big ripple currents without overheating or losing performance. Too much heat can push a capacitor past its maximum temperature and damage it, but SMILER's capacitors stay cool with great thermal management.

3. Self-Healing Properties: Their metalized polypropylene film fixes small dielectric issues on its own, making them last way longer.

4. Wide Voltage Range: With voltages from 600Vdc to 4000Vdc, they fit a ton of different needs.

5. Long Lifespan: Their sturdy build keeps them going strong, even in tough conditions.

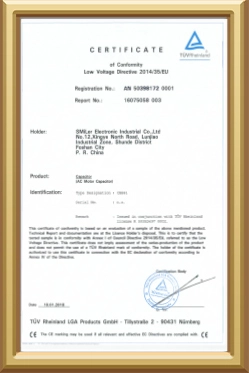

6. Meets Standards: They follow rules like GB/T 17702 (IEC 61071), ensuring they're safe and work well in industrial setups.

SMILER's DC capacitors do awesome in all sorts of places because of their flexible design:

1. Renewable Energy Systems: They're key in wind and solar inverters, keeping bus voltage steady by smoothing out fluctuations.

2. Electric Vehicles (EVs) and Hybrids: They help motor controllers handle high pulse currents without a hitch.

3. Industrial Gear: Things like welders, elevators, and motor drivers rely on their reliability and performance.

4. Power Modules: They smooth bus voltage and protect power modules during sudden changes.

SMILER's DC capacitors step up reliability with some neat design tricks:

1. Thermal Stability: They work great from -40°C to 85°C or -40°C to 80°C, depending on the model size, so they stay steady in different environments.

2. Voltage Toughness: They're tested at 1.5 times their rated voltage for 10 seconds at room temp, proving they can handle sudden over-voltages without failing.

3. Low Stray Inductance (ESL): With stray inductance as low as 10nH, they keep spike voltages in check to protect sensitive parts.

4. High Pulse Current Ability: They can handle pulse currents up to 12KA, making them great for dynamic loads.

5. Leakage Current Control: Their design keeps DC leakage current low, cutting energy waste and boosting efficiency.

6. Aging Resistance: Using top materials like metalized polypropylene film makes them tough against heat and ripple currents that speed up aging.

Q: What do capacitors do in DC circuit analysis?

A: They store energy, smooth voltage swings, zap noise, and shield parts from sudden surges or spikes.

Q: Can I use a capacitor with a higher voltage rating than needed?

A: Yup, a higher voltage rating adds a safety buffer against sudden over-voltages without hurting performance.

Q: What causes leakage current in capacitors?

A: It comes from tiny flaws in the insulating material, letting small bits of current sneak through even when not charging or discharging.

Q: How do I figure out ripple current specs for my project?

A: Check the desired temperature rise for rated temps like 85°C or 105°C, and look at manufacturer datasheets for exact numbers.

Q: How do self-healing properties help film capacitors in DC applications?