A DC Coupling Capacitor is a nifty piece in electronic circuits that lets signals zip from one stage to another without messing up the DC setup. It passes AC signals while keeping the DC bias steady for the next stage. This is super handy in amplifiers, communication gadgets, and analog front ends where you need signals to stay clean across different voltage zones. DC Coupling Capacitors sit between circuit stages. Their reactance blocks DC voltage shifts but lets wiggly AC parts through. This keeps each stage happy with its own DC level, no matter what the last stage was doing.

Circuits with DC Coupling Capacitors stay steady if the capacitor holds up. But stuff like heat, voltage stress, or aging can wear it down. This might mess with signals or shift operating points. The dielectric material and build quality matter a ton for long-term grit. High-grade film capacitors, with their Self-healing property and heat toughness, keep things running smoothly for ages.

DC Coupling Capacitors and blocking capacitors might look like cousins, but they've got different jobs. A DC Coupling Capacitor links two circuit stages while keeping their DC bias just right. Blocking capacitors, whether AC or DC, stop unwanted currents from sneaking into sensitive spots. An AC Blocking Capacitor stops alternating current but lets direct current flow, used in niche setups like bias tees. A DC Blocking Capacitor does the opposite, keeping direct current out of AC signal paths. The big difference? Coupling capacitors focus on smooth signal flow with proper bias. Blocking capacitors are all about keeping pesky currents out.

DC Blocking Capacitors pop up in RF systems, antenna hookups, and fast digital links, shielding receivers or amplifiers from harmful DC levels. AC Blocking Capacitors, often called bypass capacitors, show up in power supplies to zap AC ripple or noise before it bugs other parts. You pick these based on how they handle frequencies, impedance, and tough conditions like heat or stress.

Picking the wrong capacitor can mess things up—think garbled signals, bad biasing, or even fried parts from leaky currents. Designers need to check specs like Low ESR, capacitance wiggle room, dielectric type, voltage rating, and heat toughness to nail the right choice for their setup.

In audio gear like preamps, mixers, or equalizers, DC Coupling Capacitors keep signals clean between stages. They block hum or noise from mismatched grounds or voltage offsets. Only the good audio frequencies get through, while low-frequency drifts get the boot. This keeps speakers and amps happy. High-end audio setups love film-based DC Coupling Capacitors for their low distortion and snappy frequency response.

Medical gear like ECGs or ultrasound machines uses sensitive analog front ends where tiny voltage shifts can throw off readings. Precision DC Coupling Capacitors keep signal paths accurate without drift. In industrial stuff like motor drives or PLCs (Programmable Logic Controllers), these capacitors handle voltage spikes between control stages, staying tough under changing loads or hot conditions.

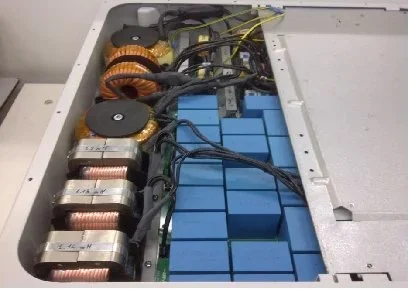

SMILER blends top-notch materials with cutting-edge manufacturing to churn out reliable gear. Our state-of-the-art automated facilities ensure efficiency, precision, and consistency, optimizing production workflows and upholding stringent quality control standards. We hit a qualified rate of finished products above 99.93% with a daily production capacity of 300,000 products. This makes our capacitors perfect for tough jobs like renewable energy or transportation electronics.

Low ESR cuts power loss at high speeds, crucial for fast-switching circuits in motor drives or communication modules. It also keeps capacitors cool, boosting reliability.

Our Voltage Range 600Vdc ~ 4000Vdc fits everything from low-voltage digital circuits to high-voltage industrial setups like electric vehicle drives or solar inverters.

With an Operating Temperature Range D≤116mm: -40˚C ~ 85˚C, SMILER's DC capacitors stay strong in harsh settings like outdoor gear or heavy machinery. The Self-healing property stops breakdowns, stretching their life even further.

Q: What is a DC Coupling Capacitor used for?

A: It passes AC signals between circuit stages while blocking DC bias shifts, keeping each stage's setup just right.

Q: How does a DC Coupling Capacitor differ from a DC Blocking Capacitor?

A: A DC Coupling Capacitor links active stages with proper bias. A DC Blocking Capacitor stops direct current from hitting certain circuit parts.

Q: Can I use any type of capacitor for DC coupling?

A: Nope. Film capacitors with Low ESR are best for their great frequency response and heat toughness compared to electrolytic ones.

Q: Why is Low ESR important in DC coupling applications?

A: Low ESR cuts energy loss at high frequencies and keeps signals clean by reducing heat inside the capacitor.

Q: Where should I place DC Coupling Capacitors in my design?

A: Put them between active amplification stages or analog input/output interfaces to keep signals sharp with correct bias.

Exploring How AC Capacitors and DC Capacitors Function Differently

Understanding DC Capacitance to Prevent Converter Oscillations

Mastering AC to DC Rectifier with Capacitor Techniques

Understanding How DC Current in Capacitor Initiates Charging

Analyzing Resistor and Capacitor in Parallel for DC Circuit Optimization