DC motor filter capacitors play a central role in reducing RFI emissions and stabilizing performance in modern motor-driven systems. DC motors inherently generate significant electrical noise during operation, making filtering essential for system reliability. Brushed motors produce sparks and broadband interference at the commutator, while brushless motors introduce high-frequency switching noise from rapid semiconductor transitions. These disturbances travel along supply lines and radiate through cables, influencing nearby circuits and risking EMC noncompliance. As both consumer products and industrial platforms become more electronically dense, understanding these noise sources is the first step toward designing reliable filtering solutions.

Filter capacitors suppress high-frequency interference by creating low-impedance pathways that divert switching noise away from sensitive nodes. When placed strategically across motor terminals or supply rails, capacitors reduce voltage spikes, dampen harmonics, and stabilize PWM-driven waveforms. In brushed motors, they absorb the transient energy generated by brush arcing. In brushless controllers, they reduce dv/dt stress and smooth high-frequency ripple. Their broad attenuation range makes them indispensable for controlling both conducted and radiated interference.

DC motor systems need to meet tough EMC rules in many uses. Weak filtering often causes failures in these checks. Home devices have to clear global emission limits. Factory automation gear must not mess with network signals. Car parts need to hold up in rough electrical spots. Today's tight designs boost ways for noise to link up. So, picking good filter capacitors is a must, not just an extra.

Ceramic, film, and electrolytic capacitors contribute differently to noise suppression, and understanding their characteristics helps engineers build effective filters. Ceramic capacitors deliver excellent high-frequency attenuation with low ESL, making them ideal for suppressing sharp switching edges. Film capacitors provide stable performance under ripple currents, high dv/dt stress, and elevated temperatures, which is valuable in PWM motor systems. Electrolytics offer high capacitance for energy buffering but provide limited high-frequency filtering. In many designs, a combination of capacitor technologies produces the best overall noise reduction.

Across-the-motor capacitors reduce differential-mode noise by controlling voltage spikes between motor terminals. Line-to-ground capacitors suppress common-mode interference that propagates through wiring harnesses and power lines. Used together, they form an effective two-path suppression method that addresses the most common noise propagation modes in DC motor systems. Placement and lead length significantly influence their effectiveness, reinforcing the importance of proper implementation.

LC networks combine the strengths of capacitors and inductors, enabling deeper attenuation across a wide frequency spectrum. Designers add inductors to increase impedance at high frequencies while capacitors shunt noise to ground. This combination is particularly beneficial in PWM-driven applications such as robotics, EV auxiliaries, and precision control modules. However, LC filters must be carefully designed to prevent resonance, voltage overshoot, or instability within control loops.

Voltage rating and ripple current capacity are basic picks for capacitors that last in motor stress. Parts that fall short wear out fast. This leads to drops in work or breakdowns. Low ESR helps spread heat well. Self-healing in metalized polypropylene film builds toughness. It fixes small breaks in the dielectric. Together, these traits keep things reliable in hard-use spots.

How a capacitor acts at high frequencies decides if it can handle quick PWM changes. Low parasitic inductance lets it keep low resistance at harmonic and switching rates. Steady dielectric work holds capacitance under high-frequency pushes. These points aid clean switching signals. They cut EMI highs and support smooth motor runs.

Environmental conditions such as humidity, heat, and vibration significantly influence capacitor lifetime. Motor systems in HVAC machinery, industrial automation, or transportation applications must rely on capacitors that maintain stable electrical behavior under such stress. Longevity is especially critical in applications with continuous duty cycles, where maintenance access may be limited.

In PWM controllers, filtering aims to cut switching wiggles. It also guards semiconductors from short stress. Capacitors at the output soak up high-frequency energy. This evens current flow and lowers EMI output. Good addition of filter parts lets motor systems meet EMC rules with extra room. It also boosts long-run dependability.

Small appliances and HVAC motors operate in close proximity to control electronics, making RFI mitigation essential. Filter capacitors help improve system efficiency, reduce audible noise, and maintain electromagnetic compatibility. Their role is especially important in variable-speed appliances where PWM signals dominate motor operation.

High-power DC motors rely heavily on filtering components to stabilize supply rails and reduce interference generated during rapid load transitions. In robotics and automated equipment, stable filtering contributes to motion precision and controller reliability. In electric vehicle subsystems, filtering helps maintain signal integrity in sensor networks and auxiliary motor circuits.

Film capacitors from SMILER capacitor have low ESR and good ripple current handling. They also show steady high-frequency work. This makes them fit well for DC motor filtering. Their metallized polypropylene build gives self-healing and long life. Even under high switching loads, they hold up. These points are backed by steady and good motor runs in factory and home use.

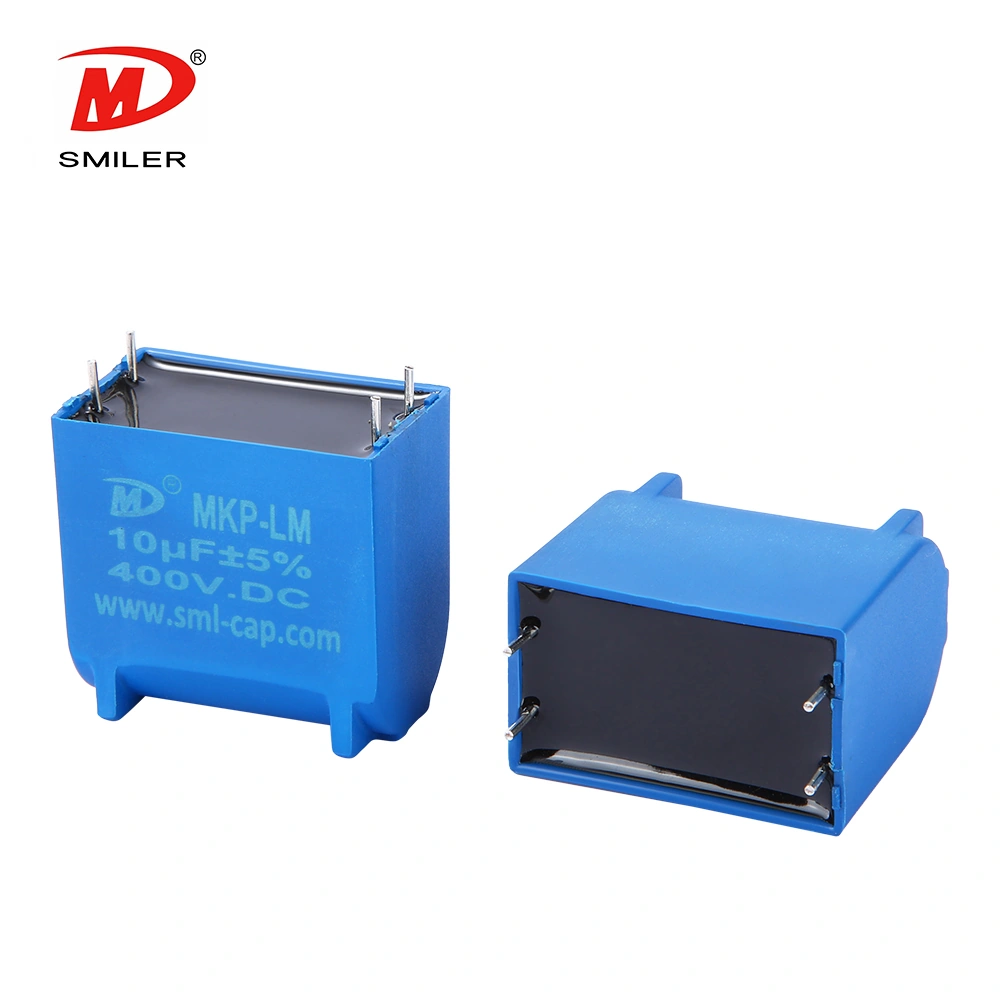

SMILER capacitor offers a few film capacitor series for DC motor filtering. The MKP-LL, MKP-L, and DC Link MKP-LM series go into motor drivers and DC setups. These need strong ripple work and low inductance. Snubber options like the MKPH-S and MKPH-LS series help high-frequency switching block near IGBT and MOSFET motor controllers. AC filter capacitors such as the MKP-AL and MKP-AM series steady output signals in speed-changing motor gear. In one factory automation job, adding MKP-LL capacitors to a robot drive cut wired noise. It also improved heat steadiness. In a home gear use, MKPH-S snubber capacitors gave cleaner switching. This helped the system clear EMC checks with better scores.

SMILER capacitor gives firm help to customers worldwide. It does this with custom specs, low minimum order amounts, and auto production lines. With deep know-how in film capacitor building, the firm brings fixes that meet the tough needs of today's motor control setups.

A: Selecting the right DC motor filter capacitor requires attention to voltage rating, ripple current capability, ESR, and high-frequency behavior. Film capacitors from SMILER capacitor offer the stability and endurance needed for PWM-driven motors.

A: Film capacitors generally provide the best RFI reduction due to low inductance and strong self-healing performance. Snubber-type film capacitors, such as those from SMILER capacitor excel at suppressing switching spikes.

A: Capacitors attenuate high-frequency noise by shunting it to ground, while inductors block noise through their impedance. Combining them in an LC filter creates a highly effective noise suppression network.

A: Automotive systems require capacitors with strong thermal stability, mechanical durability, long lifetime, and consistent high-frequency performance. SMILER capacitor offers film capacitors tested for these demanding environments.

A: Industrial motor drives need capacitors with high ripple current capacity, low ESR, and reliable insulation. SMILER capacitor provides film capacitors engineered for stable filtering in variable-speed industrial systems.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Understanding Snubber Capacitor: RC vs. RCD Snubber Differences

Understanding DC Capacitance to Prevent Converter Oscillations

What Does a CBB61 Fan Capacitor Do? Exploring the Role of CBB61 Fan Capacitors

Mastering AC to DC Rectifier with Capacitor Techniques

SMILER's Guide to Selecting the Right Snubber Capacitor Type