DC link capacitors are extremely important in effective energy transfer and storage operations within systems to guarantee stable voltage levels and ripple current management in a majority of applications, including renewable energy systems and electric vehicles (EVs). The components are crucial for noise filtering to allow operation via the reduction of power supply undulations for purposes of improved performance and system reliability.

Choice of the DC link capacitor involves some difficulties that will not be taken lightly. One such challenge is in satisfying performance specifications as well as real-world concerns such as size and temperature control. Some of the most critical considerations are concerns with whether the capacitor will function well in controlling ripple currents, be able to provide a low equivalent series resistance (ESR), and have self-healing characteristics. Furthermore, environmental factors—such as operation under a state of high humidity, heat or constant mechanical vibrations—may influence significantly how the capacitor performs and for how long.

When designing a DC link capacitor, voltage as well as current requirements must both be taken as factors for analysis. The capacitor should be the system operating voltage rated while capable of offering high enough capacitance to effectively cope with ripple currents. For instance, SMILER’s DC Link MKP-LL capacitors range from 600 volts to 4000 volts, and this versatility can be exploited in many high-power applications such as motor drive systems and industrial inverters.

Capacitance value helps decide the efficiency of a capacitor to store charge and block unwanted signals. The higher capacitance value makes the capacitor more efficient in terms of handling currents. However, it may also lead to larger physical dimensions or reduced thermal effectiveness. SMILER offers a range of products tailored to requirements, spanning from 24μ F to 5600μ F in capacitance. Our employment of polypropylene film ensures minimal ESR contributing to exceptional performance even in challenging environments.

Maintaining the temperature is vital when designing DC link capacitors as heat can wear down the materials and shorten their lifespan over time. SMILER tackles this problem by using resin filling, which helps to dissipate heat effectively. In addition to this feature, our capacitors are known for their self healing abilities, which enhance reliability by isolating damaged areas within the material automatically.

In settings having reliable and effective electrical parts is crucial. DC link capacitors play a significant role in the functioning of inverters motor driver systems, welders, and lifts. In industrial applications, capacitors must endure high ripple currents, resist repeated voltage fluctuations and work best under worst-case conditions. For instance, in motor drives or inverters, high capacitance and robust voltage ratings are essential for power conversion without any interruptions. The environmental conditions, such as temperature conditions and humidity, also influence the selection of material and the design to ensure that the lifespan and consistency of the capacitor are sustained within specific industrial conditions.

Wind turbines and solar inverters in energy setups require special DC link capacitors that can withstand temperature changes and high humidity levels typically found in these environments. To address these challenges capacitors utilized in systems must demonstrate reliability and resilience to environmental conditions. The DC Link MKP-LM series by SMILER is a choice for renewable energy applications due to its superior resistance to humidity and operating temperature range of 40°C to +105°C. This ensures performance in harsh weather conditions.

Wind turbines and solar inverters in energy setups require special DC link capacitors that can withstand temperature changes and high humidity levels typically found in these environments. To address these challenges capacitors utilized in systems must demonstrate reliability and resilience to environmental conditions. The DC Link MKP-LM series by SMILER is a choice for renewable energy applications due to its superior resistance to humidity and operating temperature range of 40°C to +105°C. This ensures performance in harsh weather conditions.

One of the most prominent characteristics of energy systems is that high capacitance values in small packages must be used to obtain high efficiency and performance. SMILER meets this need by providing capacitors that balance large capacitance with compact size. Their high overcurrent and overvoltage resistance offer an additional degree of electrical surge protection and enhance system reliability. The features enable SMILER's capacitors to effectively meet the renewable energy applications' filtering and energy storage needs.

The automobile sector is experiencing a shift to hybrid electric vehicles (HEV) and electric vehicles (EV). The development in this sector demands high-performance parts that are capable of attaining standards of operation efficiency and reliability. In the sector, DC link capacitors play a key role in maintaining stable voltage levels within DC converters and powertrain systems. DC fast-charging technology is an important element, providing drivers with enough energy for long distances in a short charging time, especially on long journeys. In the future, DC charging technology will also be available for private charging, on the one hand, to use the driver’s own solar power and on the other hand to use the car as a storage medium. The efficiency of the charging station is an important performance feature. SMILER offers components with minimal power dissipation for this purpose.

SMILER develops state-of-the-art DC link capacitor designs that go beyond being components to offer customized solutions, which address the complex requirements of today’s electrical systems across various sectors, such as renewable energy and transportation as well as industrial applications. The capacitors from SMILER are known for their performance and dependable nature.

The key to crafting a top-notch capacitor lies in the choice of materials it is made from. SMILER opts for polypropylene film for its DC link capacitors. This particular substance is renowned for its electrical characteristics, such as low equivalent series resistance (ESR) and high efficiency in handling ripple currents. To boost longevity the capacitors sport packaging in either aluminum or plastic shell along with resin filling (UL94 V-0), which not only aids in better heat dispersal but also offers fire-resistant qualities.

The exceptional feature of these capacitors is their ability to self heal, which guarantees that any small breakdown in the dielectric is promptly contained to uphold the functionality and prolong the products lifespan. This characteristic makes SMILER’s capacitors especially ideal for settings where reliability is crucial.

In industries with distinct needs and specifications, the one-size-fits-all approach may not always be suitable. Thus, SMILER provides a range of customization choices for the DC link capacitors to address this diversity effectively. Customers have the flexibility to define voltage ranges capacitance values and even physical dimensions according to their requirements.

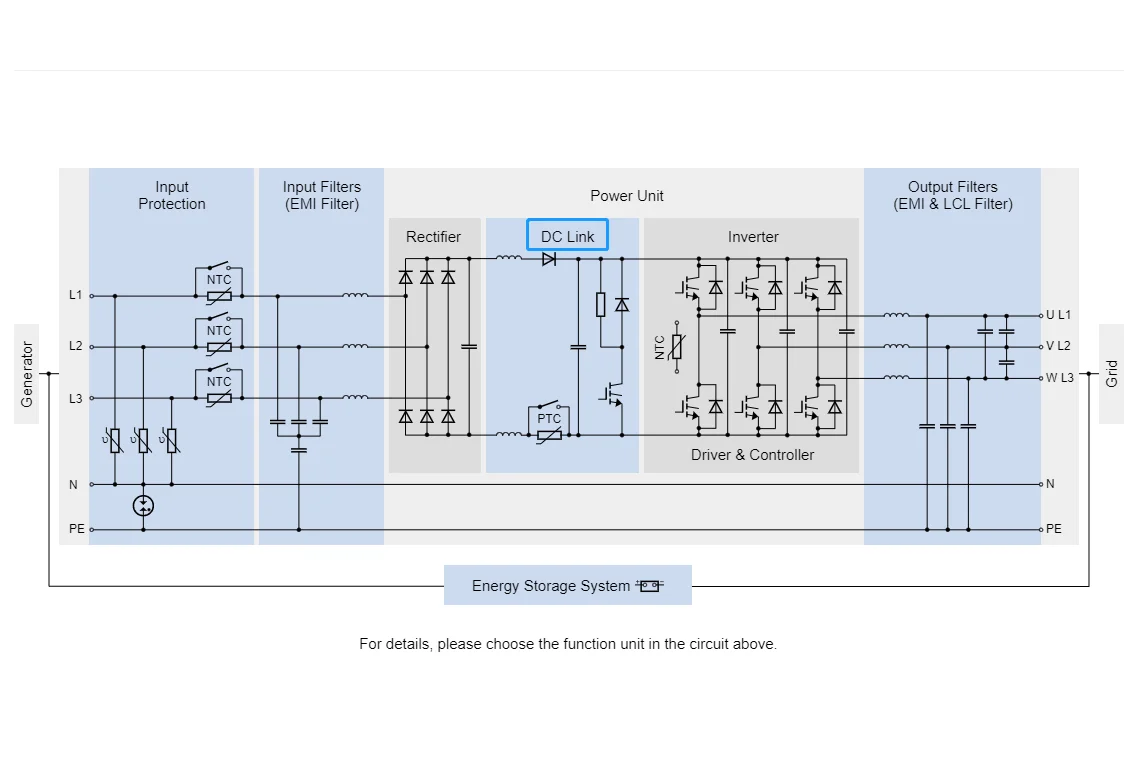

A: A DC link capacitor is used in power electronic systems to filter voltage oscillations, improving power quality. It acts as a filter between the inverter and the DC supply, ensuring stable operation and efficiency in devices like inverters and motor drives.

A: DC link capacitors reduce voltage ripple and energy storage to provide a stable voltage supply. They are also crucial in power loss reduction, improving system efficiency, and increasing the life of power electronic devices by sustaining voltage stability levels.

A: Choose a DC link capacitor based on characteristics like voltage rating, capacitance, ripple current, and conditions of environmental use. Your selected capacitor must support maximum specified voltage and changes in currents so that they can continue to be dependable under your specific use.

A: Standard DC link capacitors include electrolytic, ceramic, and film capacitors. High capacitance can be provided through the use of electrolytic capacitors, but in high-frequency applications, where stability with little loss is more sought after, ceramic and film capacitors can be utilized.