The DC link plays a role in the power conversion setups of contemporary electric cars (EVs). It acts as a connector linking parts of power electronic circuits, like the AC to DC rectifier and the high frequency converter for DC to DC operations within an EV Fast Charger unit. This middleman position guarantees the transfer of electrical power between different phases while upholding steadiness.

The most critical function of a DC link is to attenuate voltage ripple caused by load fluctuations or other disturbances. It is particularly critical in EVs where power consumption can switch enormously quickly, e.g., when accelerating or regenerative braking. By providing a stable voltage level, the DC link enables efficient and fault-free operation of the vehicle's motor drive system.

Efficiency in automobiles is critical as it has a direct influence on their range and capability to perform. DC link is vital in ensuring that maximum efficiency is achieved because it reduces wastage of energy during power conversion processes. For instance, in the process of converting AC power from the mains to DC power for battery charging or vice versa when regenerative braking is used, the DC link reduces energy loss.

Additionally, minor components in the DC link like film capacitors are important in helping to minimize power loss and enhance overall system performance. The effectiveness of the charging station stands out as an aspect of its performance. SMILER provides components that minimize power loss to meet this requirement. These innovative capacitors not only boost energy storage but also guarantee lasting dependability in different operational situations.

DC link stability enhances the performance of an electric vehicle through the delivery of a steady supply of voltage to key elements such as inverters and motor drives. Such reliability leads to smooth acceleration and torque control and less wear and tear on electronic devices.

DC link stability enhances the performance of an electric vehicle through the delivery of a steady supply of voltage to key elements such as inverters and motor drives. Such reliability leads to smooth acceleration and torque control and less wear and tear on electronic devices.

Instability within the DC connection could result in voltage fluctuations or vibrations, that might lead to inefficiencies or harm electronic components in the vehicle. To tackle these issues, ensure smooth operation under high frequency switching and abrupt load variations manufacturers develop sturdy DC links that maintain stability.

Fluctuations in voltage are bound to happen in systems with changes like electric vehicles. However, it's essential to handle these fluctuations to keep the performance at its best and make sure the components last longer. Advanced capacitors in the DC link play a role in absorbing sudden voltage spikes and keeping a stable output flow.

To lessen CO₂ emissions worldwide, the shift towards e-mobility is picking up steam. SMILER is coming up with tailor-made solutions to meet these demands. Their metalized film capacitors are crafted to manage ripple currents and offer top-notch thermal stability, which makes them perfect for electric vehicle use. By integrating their cutting-edge elements into electric vehicle systems, makers have the potential to reach increased efficiency, reliability and functionality— elements for fulfilling consumer demands in today's competitive market landscape.

Managing heat in the DC circuits of today’s cars is crucial due to their growing power requirements as technology progresses in this area of transportation. The rising power density in these components results in heat being produced and if not managed properly can impact the efficiency and durability of the system over time.

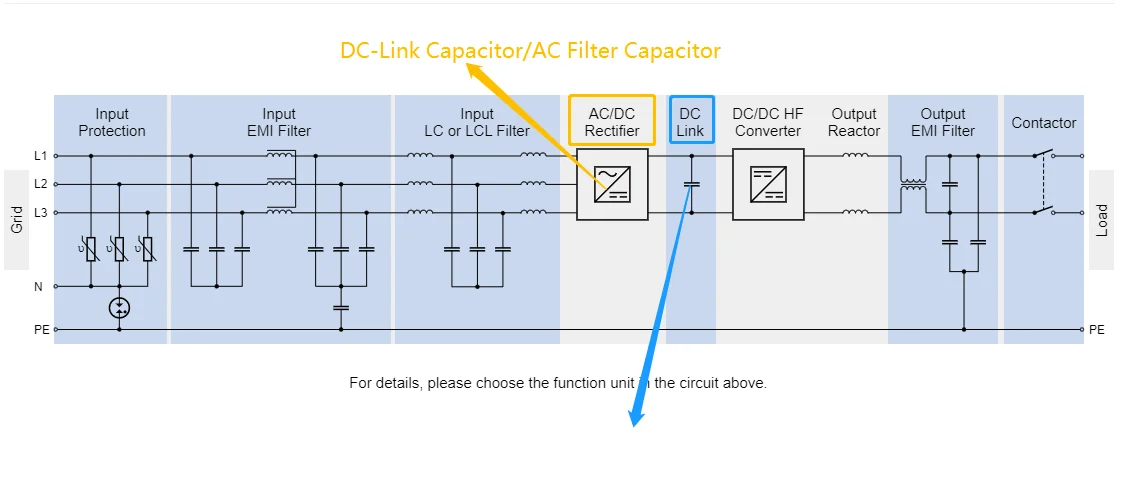

DC has access to power that undergoes various difficulties in the efficient management of heat dissipation due to the rapid-switching operations conducted in power electronics, which results in intense heat generation that needs to be dissipated properly for system stability in the entire EV Fast Charger system, where capacitors have various functions at the DC Link and DC to DC HF Converter stages, inefficient thermal management may cause problems like voltage oscillation, reducing the life of capacitors or even causing severe electronic component failure.

To counteract these problems, manufacturers employ various techniques to enhance the thermal efficiency of DC links in EVs. One of the most popular techniques is the use of superior materials with superior thermal conductivity properties. For instance, metalized film capacitors are widely used in DC links due to their satisfactory heat dissipation properties and superior reliability at high temperatures.

Another effective approach is to optimize the design of cooling systems in EVs. Liquid-based cooling systems are currently employed in high-power applications in an effort to ensure efficient heat removal from key components such as the DC link. Passive cooling techniques such as improved airflow design and thermal insulation materials are also crucial in dissipation of heat.

SMILER's DC connection solutions are designed to address the requirements of current electric cars, guaranteeing g optimal efficiency and dependability. One standout feature of these DC connections is their capacity to maintain voltage levels throughout different power conversion phases. Throughout the entirety of an EV Fast Charger, our capacitors play a role in various areas: DC Connection, AC / DC Rectifier and DC / DC HF Converter. This functionality is vital in EV scenarios where sudden shifts in power needs can result in fluctuations.

Additionally, SMILER emphasizes efficiency in its designs by utilizing components in their DC links, that reduce power dissipation during energy transfer processes effectively. The performance of the charging station is significantly influenced by its efficiency and SMILER provides components designed to minimize power loss for this purpose. This commitment to decreasing energy wastage not only improves vehicle range but also contributes to worldwide efforts to promote sustainable transportation solutions.

The selection of materials is crucial for how an electronic device functions and SMILER stands out for this reason. Their DC connections feature quality metalized film capacitors that are praised for their stable heat resistance and ability to handle large ripple currents effectively. As the world pushes towards lowering CO2 emissions on a scale, electric vehicles are becoming more popular. These capacitors guarantee that the DC connections can perform optimally even when faced with situations, like frequent rapid switching or sudden shifts in load.

SMILER is known for the durability of their products, their DC link solutions which are built to endure tough conditions without sacrificing performance quality. The strength of these products comes from engineering and the use of high quality materials.

The film capacitors with metal coatings in these items are designed to withstand changes in temperature and electrical stress and are recommended for uses with frequent power fluctuations or temperature changes. Additionally, SMILER implements quality checks at every stage of production to guarantee that each part meets strict reliability criteria.

The emphasis on being corresponds with the overall objectives of the industry to decrease carbon emissions while satisfying consumer demands for convenient and dependable electric transportation options. SMILER meets the constantly changing requirements of contemporary electric vehicles through continuous innovation and a commitment to first-class quality.

A: A DC link is a connection between two or more power conversion stages that exists in power electronics. It consists of a capacitor that serves as its primary component to store energy, filtering voltage and current ripple between stages such as rectifiers and inverters. The primary function of the DC link is to store energy when output power is lower than input power and release it back when the requirement is higher output power compared to the input power.

A: The control of power in a DC link can be achieved through the control of current or voltage. From minimization of loss considerations, we need to maintain constant voltage in the link and adjust the current to meet the required power.

A: The high voltage DC links may be classified into: 1. Monopolar Link 2. Bipolar Link 3. Homopolar Link.

A: Plugging in your plug-in hybrid electric vehicle (PHEV) or all-electric vehicle (EV), both of which are more generally known as plug-in electric vehicles (PEVs), is not significantly more difficult than plugging in other household appliances. A portion of an electric cord gets plugged into your car, and the other end gets plugged into a power outlet or charger.

A: Yes, EV charging is cheaper than refueling an electric car. Though the price of electricity will vary by region, the price to charge an EV is generally cheaper than the price of gasoline, especially if charged at home.