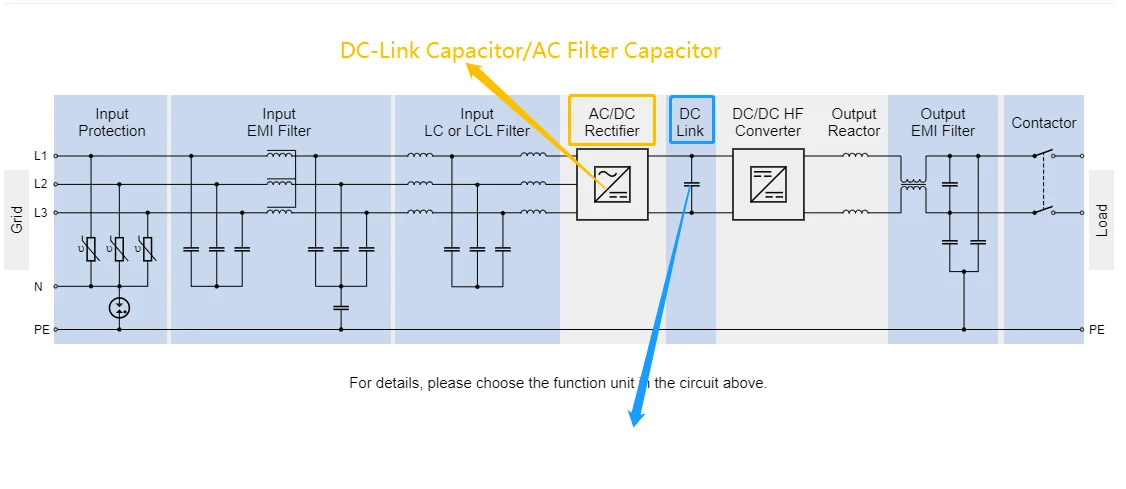

Electric vehicle charging stations (EVs) play a crucial role in promoting e-mobility adoption by providing quick recharging of power on long trips. DC capacitors are one of the most crucial elements in these installations for maintaining a smooth and reliable supply of power. SMILER's capacitors are employed at points in the EV Fast Charger, for instance, the DC Link area the AC to DC Rectifier part and the DC to DC HF Converter part of the system.  These capacitors are crucial for controlling power variations and maintaining voltage levels while also temporarily storing energy to fulfill the fast charging requirements efficiently.

These capacitors are crucial for controlling power variations and maintaining voltage levels while also temporarily storing energy to fulfill the fast charging requirements efficiently.

DC capacitors help in meeting high power needs while maintaining levels of optimal performance for EVs' fast chargers. DC capacitors are required in an effort to give a source of energy during maximum usage to meet the speed and efficiency levels that are needed in electric vehicles of today.

Energy efficiency is one of the attributes of sustainable technology and this holds for EV fast chargers as well. DC capacitors aid in enhanced efficiency in the systems by reducing loss of power and enhancing overall performance. The performance of the charging station in terms of efficacy is one of its characteristics. Suppression of voltage oscillations and minimizing energy loss during conversion processes they provide a smooth operation that is guaranteed at all times.

In addition, DC capacitors help minimize the generation of heat in the system, which reduces damage to the parts. Not only does this increase the longevity of the charger, but it also means more energy is put into charging the car instead of generating heat. This leads to an environmentally friendly and economical solution for both operators and consumers.

Ensuring Stable Power Delivery with SMILER’s DC Capacitors

Ensuring Stable Power Delivery with SMILER’s DC CapacitorsWith over 15 years of expertise in film capacitors, we bring unparalleled knowledge and experience to every project. SMILER’s products are designed to ensure stable power delivery under varying load conditions, which is a critical requirement for fast chargers that must handle sudden surges in demand.

The DC Link MKP-LM has a large capacitance with a small size. The high reliability, self-healing properties and long lifetime make it ensuring voltage levels throughout various charging stages to avoid interruptions that might impact user satisfaction or harm delicate electronic devices.

Rapid charging comes with a set of difficulties because of the high power demands involved in the process. SMILER’s DC capacitors tackle this issue by cutting down on power wastage during energy transfer. SMILER provides components that have power loss specifically for this purpose. These components are designed with technology to ensure that a larger amount of energy is effectively delivered to the vehicle battery while also decreasing unnecessary waste.

In situations of demand and stress electrical systems can be tough to handle. However, SMILER’s DC capacitors are designed to endure such situations effectively due to their strong build and innovative materials that enable them to function consistently even in harsh conditions. For example, the DC Link MKP-LS uses tinned copper terminals as leads. With a plastic shell or Mylar tape housing, it is widely used in AC/DC filtering, high frequency and high current applications as well as UPS, electric vehicles and so on.

These capacitors play a role by maintaining reliable performance even during busy times to avoid interruptions and make sure electric vehicle drivers have access to fast charging stations whenever they need them the most. In turn, this consistent reliability is essential for establishing trust among consumers towards electric mobility solutions.

DC-Link capacitors play a critical role in EV fast chargers by stabilizing the DC bus voltage and mitigating high-frequency noise generated during rapid power conversion. In high-voltage architectures (e.g., 800–1200V systems), metalized film capacitors are preferred over electrolytic types due to their higher voltage ratings, ultra-low ESL and superior thermal stability. These capacitors absorb voltage spikes caused by SiC semiconductor switching, protecting power modules from damage.

Customized designs with capacitance ranges of 1–3000µF ensure energy buffering during high-current pulses, essential for fast charging cycles. Their low inductance minimizes voltage overshoot, enhancing efficiency in bidirectional chargers. Integration with SiC-based inverters reduces losses, while compact, modular builds suit space-constrained installations. Additionally, their durability in high-temperature environments and resistance to electrolyte degradation ensure reliability over long-term operation, aligning with the demands of ultra-fast charging infrastructure.

In conversations about energy storage in DC applications capacitors are players but they vary in quality and performance level. SMILER’s capacitors are designed with cutting edge materials that enable them to store electrical energy in their electric fields with minimal wastage. This feature makes them suitable for long-term energy storage needs in various applications, such as industrial automation systems or renewable energy installations. Such capacitors from SMILER offer effective solutions for a range of power-related tasks.

The stored energy in a capacitor can be put to use in different real-world scenarios. Especially when utilizing SMILER’s top-notch products! For example, within power supply setups where SMILER’s capacitors serve as reservoirs that help regulate voltage changes and ensure steady power flow to delicate electronic parts. Their quick release of stored energy is vital in tasks such as powering camera flashes or operating pulsed laser systems effectively.

SMILER’s capacitor designs prioritize dependability above all else by subjectinc their products to testing for consistent performance in diverse conditions. For example, the DC Link MKP-LM is engineered to endure varying temperatures and environmental pressures ensuring functionality even in challenging situations.

SMILER’s capacitors stand out for their ability to sustain stable capacitance levels over time—a key factor in maintaining stability in DC circuits where consistency is vital for optimal performance whether you’re creating intricate electronic gadgets or robust industrial equipment. SMILER’s capacitors offer the dependability essential for seamless operation of your systems.

A: When capacitor is connected to dc voltage source, capacitor starts the process of acquiring a charge. This will built up voltage across capacitor. Once capacitor has acquire enough charge, current starts flowing and soon capacitor voltage reaches at value approximately equal to dc source voltage.

A: Capacitors can be used as temporary storage devices after being connected to DC voltage. Once fully charged the capacitors will stop allowing any more electrons to reach the plates. Thus the capacitor stops the DC once it is fully charged.

A: When using polarized capacitors, its positive pole must be connected to the higher voltage (current input) and its negative pole to the lower voltage (current output/e.g. ground). In these capacitors, the negative pin (shorter leg) is marked on the body with the sign “-” above the pin.

A: Low ESL (≤10nH) minimizes voltage spikes during switching, protecting semiconductors like IGBTs/SiC MOSFETs. The rated voltage must exceed the system’s peak voltage (e.g., ≥1200VDC for 800V bus systems) to prevent breakdown. Capacitance (1–3000µF) determines energy storage for smoothing voltage ripples, while pulse current ratings (up to 30kA) ensure stability under transient loads. Custom designs integrate these parameters for applications like EV motor controllers, balancing compactness, thermal performance and EMI reduction. Testing ensures compatibility with module-specific voltage/current profiles.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Exploring How AC Capacitors and DC Capacitors Function Differently

Understanding Snubber Capacitor: RC vs. RCD Snubber Differences

Understanding DC Capacitance to Prevent Converter Oscillations

What Does a CBB61 Fan Capacitor Do? Exploring the Role of CBB61 Fan Capacitors