An AC coupling cap is essential for eliminating unwanted DC components in modern electronic and power-conversion systems. By removing the DC offset, the AC coupling capacitor ensures accurate waveform transmission and protects sensitive downstream circuits. This function is fundamental in amplifiers, measurement chains, inverter outputs, and communication circuits that require clean AC waveforms free of drift or bias.

An AC coupling cap blocks DC components by presenting high impedance to DC while maintaining low impedance for AC signals. This selective behavior makes the capacitor act as a high-pass filter, allowing alternating components to pass to the next stage. In power electronics, this mechanism prevents DC shifts from damaging control circuits or driving sensors out of their linear operating range, especially when monitoring current or voltage in fast-switching systems.

Engineers use AC coupling in filters, amplifiers, and signal-conditioning circuits to maintain signal integrity across varying load and environmental conditions. AC coupling ensures that measurement devices interpret only the alternating component of interest while ignoring low-frequency noise or drift. In industrial inverters, AC coupling improves sensor accuracy, prevents operational saturation, and contributes to stable feedback control during dynamic load transitions.

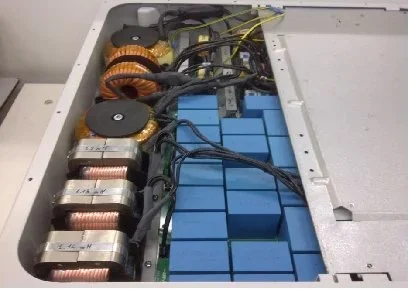

AC coupling capacitors need strong ripple-current handling, low ESR, low inductance, and good self-healing traits. These features matter because AC coupling caps in power electronics face fast voltage changes, high harmonic levels, and heat pressure. SMILER capacitor’s film-capacitor technologies fit well. In particular, the metallized polypropylene build in their AC-Filter Capacitor and Snubber Capacitor series gives the electrical steadiness required for coupling jobs in tough spots.

Signal integrity, noise rejection, and frequency behavior change significantly depending on whether AC coupling or DC coupling is used. AC coupling filters out the DC portion and is well-suited for waveform-based analysis, while DC coupling preserves the full signal, including its offset. Engineers must examine which method maintains measurement accuracy within the system's operating conditions.

AC coupling is the better choice when the DC bias is irrelevant or harmful to circuit operation. For example, photovoltaic inverters and EV fast chargers often incorporate AC coupling in their sensing units to suppress slow DC drift caused by multi-stage conversion processes. AC coupling improves the accuracy of current transformers and hall-effect sensors by ensuring the monitored waveform remains centered around zero.

Limitations of AC coupling arise when low-frequency content is essential for system behavior. If the cutoff frequency of the AC coupling cap is set too high, it can distort slow AC components, reducing measurement precision. Applications such as grid-synchronization control, energy-storage conditioning, or precision metering often require DC coupling instead. Choosing the right coupling method ensures that critical information is not lost.

Capacitance, frequency response, and input cutoff characteristics drive the selection of an AC coupling cap for demanding applications. Engineers must size the capacitance to ensure the high-pass cutoff sits well below the lowest relevant frequency. Oversized or undersized values can distort waveforms or introduce unwanted phase shifts.

ESR/ESL, ripple-current capability, and high-frequency stability directly influence the longevity and reliability of an AC coupling capacitor. Metallized polypropylene film capacitors from SMILER capacitor, such as their AC-Filter Capacitor (Dry-Type, Aluminum Case) and AC-Filter Capacitor (Plastic Case), provide low ESR and minimal inductance to maintain stable coupling in high-frequency converters. These construction advantages allow the capacitor to retain consistent performance even in harmonic-rich environments.

Material selection strongly affects performance, and metallized polypropylene film dominates AC coupling applications because of its low dielectric loss, superior stability, and self-healing properties. SMILER capacitor uses this material in series, such as the MKP-LM DC-Link Capacitor and MKP-LL DC-Link Capacitor, which are often placed in AC/DC front-end filtering stages that cooperate with AC coupling circuits. The film provides long-term durability under repeated high-frequency voltage stress.

Safety, reliability, humidity resistance, and lifetime performance must be evaluated when selecting an AC coupling cap. Many industrial environments experience high humidity, thermal cycling, and strong mechanical vibration. SMILER capacitor's THB-grade film capacitors and Snubber Capacitors exhibit proven resistance to 85°C/85%RH testing and deliver stable performance during long-duration endurance cycles. This reliability is crucial for systems requiring uninterrupted coupling performance over years of operation.

AC coupling capacitors in power conversion systems enable precise waveform shaping, harmonic reduction, and robust feedback control. Their role extends far beyond simple filtering, as they actively contribute to system stability in demanding grid-connected and off-grid environments.

AC coupling capacitors in inverters, EV chargers, and renewable-energy converters support accurate sensor readings, minimize DC bias errors, and stabilize waveform amplitude. In one SMILER capacitor application, an AC Filter Capacitor was installed at the output stage of a 50-kW solar inverter to refine high-frequency ripple content. After installation, the inverter achieved smoother AC output and reduced thermal stress on switching devices, demonstrating the importance of proper AC coupling design.

AC coupling plays a critical role in UPS output filtering, motor-drive control loops, and high-frequency converters. In industrial motor drives, AC coupling ensures that feedback signals remain centered during start-stop cycles and mechanical load fluctuations. A manufacturing plant utilizing SMILER capacitor's Snubber Capacitor and AC-Filter Capacitor reported stable operation and lower EMI, leading to improved uptime in their automated lines.

AC coupling supports harmonic control and EMI reduction by suppressing low-frequency drift and allowing filters to target specific harmonic bands more effectively. Film capacitors used in AC coupling help maintain linearity in the presence of switching transients. When combined with SMILER capacitor's MKP-based designs, these systems benefit from reduced noise propagation and enhanced grid compliance.

SMILER capacitor delivers reliable AC coupling performance by combining advanced metallized polypropylene film technology with automated manufacturing and a proven self-healing structure. These design features ensure stable capacitance, low losses, and consistent operation even under high ripple stress or prolonged thermal exposure. The company's qualification rate above 99% reflects the durability needed for industrial AC coupling environments.

SMILER capacitor offers several product series suitable for AC coupling and AC filtering functions in power-conversion architectures. Their AC-Filter Capacitor (Dry-Type, Aluminum Case) is widely used in inverter outputs and harmonic-mitigation networks, while the AC-Filter Capacitor (Plastic Case) provides compact, high-humidity-resistant performance for UPS and charging systems. The MKP-LM and MKP-LL DC-Link Capacitors, although primarily used on the DC-bus, work alongside AC coupling sections in AC/DC rectification stages, ensuring stable energy transfer and low ripple. The Snubber Capacitor further complements AC coupling by controlling voltage spikes and enhancing waveform stability.

Industries using SMILER capacitors for AC coupling circuits cover solar-energy systems, EV charging builds, wind-power converters, factory motor drives, and UPS makers. These fields count on exact AC filtering and coupling work to meet world standards and keep long-term reliability.

A: An AC coupling cap is used to block DC components while allowing AC signals to pass through, ensuring measurement accuracy and stable signal processing. SMILER capacitor provides film capacitors designed for reliable AC coupling in renewable energy, EV charging, and inverter applications.

A: Selecting the right AC coupling cap requires evaluating capacitance, ripple-current capability, ESR/ESL levels, and thermal stability. Film capacitors from SMILER capacitor, including AC-Filter and MKP-series designs, offer stable performance in high-frequency inverter environments.

A: Film capacitors are generally better for AC coupling because of their low ESR, low inductance, and excellent self-healing behavior. SMILER capacitor's polypropylene film construction ensures stable AC coupling performance even under high ripple and switching frequencies.

A: Applications that benefit most include inverter output sensing, UPS waveform correction, EV charger filtering, and motor-drive feedback loops. Projects using SMILER capacitor AC-Filter Capacitors have demonstrated improved waveform clarity and reduced EMI.

A: The recommended type is a metallized polypropylene film capacitor because it withstands high ripple and maintains stable capacitance. SMILER capacitor's AC-Filter Capacitor and Snubber Capacitor series are widely used in industrial converters requiring reliable AC coupling behavior.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Understanding DC Capacitance to Prevent Converter Oscillations

Mastering AC to DC Rectifier with Capacitor Techniques

SMILER's Guide to Selecting the Right Snubber Capacitor Type

Analyzing Resistor and Capacitor in Parallel for DC Circuit Optimization

Unveiling the Mechanics of Snubber Condensator in Power Systems