A ceiling fan capacitor 4uf gives the motor the extra push it needs to start turning. The blades are heavy, so the motor needs a second current that is out of step with the main one. The 4uf capacitor makes that second current. Once the fan spins, the same capacitor keeps the speed steady. It holds the right gap between the two currents in the motor. That gap stops the fan from shaking and keeps the speed where the maker wanted it. In homes, offices, or shops, a good 4uf capacitor lets the fan reach full speed fast without getting the coils too hot.

Capacitance accuracy matters because a ceiling fan capacitor 4uf is engineered to match the impedance characteristics of the motor coil. When the capacitance is correct, the fan runs at its designed efficiency, with minimized current draw and controlled acoustic noise. If the capacitance deviates significantly, the motor may experience imbalanced magnetic fields, leading to hum noise, energy waste, or reduced torque. Maintaining precise capacitance is therefore essential for fans installed in hotel rooms, offices, and residential spaces where temperature control and acoustic comfort are both crucial.

A 5uf capacitor pushes more current into the start winding than the motor expects. The fan starts faster and often spins a bit quicker than normal. That sounds good, but the extra current makes the winding hotter. You can also hear a louder hum because the magnetic fields are no longer balanced. It might run for a while, yet the heat builds up slowly and shortens the motor's life.

With 5uf instead of 4uf, the start winding sees higher current all the time the fan runs. More current means more heat in the thin wires. Older fans have insulation that is already dry. Extra heat makes it crack faster. In the worst case, the thermal protector trips, and the fan stops until it cools down.

The blades now turn faster than the maker planned. The extra speed can make the fan wobble a little or make the housing rattle. In big commercial fans that run twelve hours a day, that small wobble wears the bearings quicker.

Using a 5uf capacitor as a replacement can be acceptable when the fan requires temporary maintenance and no 4uf unit is immediately available. In such cases, the priority is restoring basic operation until the correct capacitor can be sourced. However, long-term substitution should be avoided to prevent accelerated motor degradation.

Use 5uf only when the fan stays on low speed most of the time, and the room is not too hot. An office fan that runs for a few hours a day will probably be fine for a short period.

High-risk conditions include high-temperature environments, continuous-operation fans, or installations where precise airflow control matters—such as hotel HVAC ceiling fans or agricultural ventilation systems. In these settings, maintaining the original 4uf value is essential to avoid unstable performance or shortened equipment life.

Choosing the correct ceiling fan capacitor 4uf replacement requires matching not only capacitance but also voltage rating, frequency rating, and tolerance. The voltage rating must exceed the peak AC voltage to prevent dielectric breakdown. A typical ceiling fan capacitor uses polypropylene film with self-healing properties, allowing safe operation even under momentary surge conditions. Additionally, capacitance tolerance affects how closely the capacitor performs to its stated value; tighter tolerances are preferred for fans requiring consistent RPM.

Motor capacitors used in ceiling fans typically fall under thin-film AC motor-run capacitor designs, such as compact plastic-cased units or cylindrical film capacitors. CBB61-style capacitors are widely used due to their small form factor and safety features. CBB60 units are generally larger and designed for pumps or heavier loads, while dual-value capacitors combine two capacitances to support multi-speed operation. The correct configuration depends on whether the fan uses a single-value or dual-value control circuit, making verification essential during replacement.

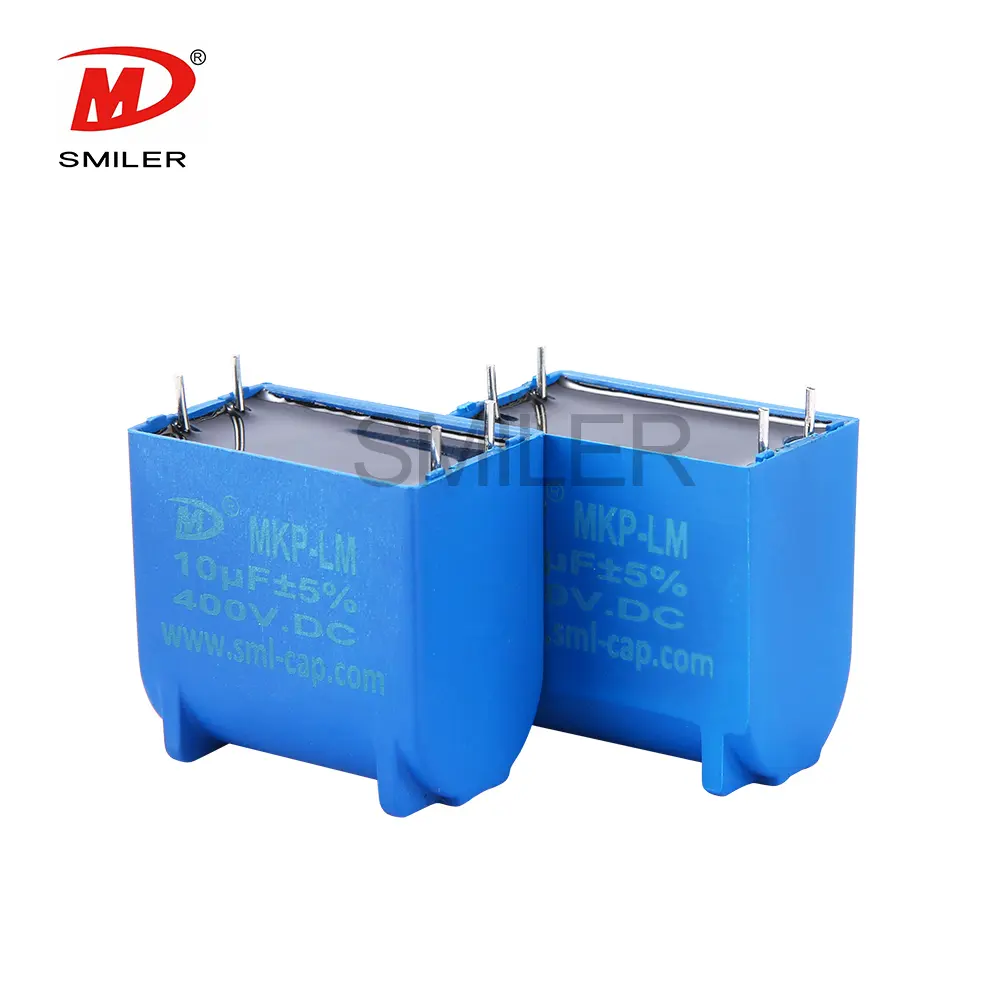

CBB61 capacitors are square plastic boxes filled with thin film. They fit perfectly inside the fan housing and weigh almost nothing. The film can fix tiny faults by itself, so the capacitor keeps working even after years of daily use.

A very thin metal layer is sprayed on the plastic film. If a small spark happens, the metal around it burns away, and the capacitor heals itself. That is why good CBB61 units last ten years or more.

CBB61 capacitors support smooth fan startup, reduced acoustic noise, and sustained torque output. Field installations—such as a recent project equipping ceiling exhaust fans in a commercial kitchen—demonstrated stable startup even under fluctuating voltage conditions. By integrating a CBB61 4uf capacitor from SMILER capacitor, engineers saw significantly improved running stability and reduced coil heating after extended operation.

Sometimes a CBB60 fits the holes, but it is heavier and can make the fan housing vibrate. CBB65 oil-filled types are made for air-conditioner compressors – they are too big and heavy for ceiling fans.

CBB61 Capacitor is dry and light. CBB60 and CBB65 Capacitor often have oil inside and metal cases. The extra weight pulls on the fan motor shaft and can cause early bearing wear.

They are built for heavy pumps and compressors that need much more current. A ceiling fan only needs a small, light capacitor that matches exactly.

SMILER capacitor makes capacitors specially for small motors like ceiling fans. Their factory uses modern machines and strict checks so every piece works the same.

The SMILER capacitor CBB61 boxes are small, flame-proof, and resist humidity well. In a seaside hotel last summer, their capacitors kept the fans running perfectly, even with salty air.

SMILER capacitor products undergo rigorous quality control, delivering low dissipation factors and stable performance in varying temperatures. This reliability supports ceiling fans used in continuous-run environments such as office buildings, supermarkets, and restaurant dining halls.

They hold UL, CQC, CE, and VDE certificates. That means the capacitors are safe anywhere in the world.

These marks prove the capacitors pass tough safety tests. Installers and factories trust them without worry.

Even small fan makers can order exactly what they need – different wire length, special box colour, or tighter tolerance.

A: SMILER capacitor is a safe choice. Their CBB61 units use good film and a self-healing design that lasts many years.

A: Check the fan manual or measure the old one. SMILER capacitor can help you pick the right value and voltage.

A: Only for a very short time and at low speed. For normal use, always go back to the correct 4uf SMILER capacitor.

A: CBB61 is the best fit – small, light, and made exactly for ceiling fans. SMILER capacitor makes top-quality CBB61 units.

A: Look at the wires. Two wires usually mean a single 4uf. Three or four wires often mean dual-value. SMILER capacitor supplies both types.

What Does a CBB61 Fan Capacitor Do? Exploring the Role of CBB61 Fan Capacitors

DC Link Capacitor Design: A Comprehensive Selection Guide

Understanding Capacitor Filter Circuit: Frequency and Value Relationship

Choosing the Right Filter Capacitor for Induction Cooker: An In-Depth Guide

Capacitor Voltage Regulator: Unveiling Hidden Drawbacks