DC blocking capacitors are essential components in signal integrity applications because they prevent unwanted DC bias from interfering with AC signals. In high-speed or sensitive analog circuits, even small DC offsets can alter signal baselines, disrupt voltage thresholds, and degrade data accuracy. By acting as AC coupling elements, these capacitors isolate different stages of a circuit while preserving the integrity of the AC signal.

Furthermore, DC blocking capacitors are widely used to maintain signal fidelity by decoupling active components, such as amplifiers or transceivers, from each other. This isolation helps prevent biased conflicts and minimizes crosstalk between channels. These functions are particularly important in modern RF systems, communication networks, and high-speed data interfaces where stable signal transmission is critical.

In high-frequency communication systems, such as Ethernet or HDMI, these capacitors enable proper operation by allowing only the desired signal frequencies to pass while blocking harmful DC components that could otherwise saturate receivers or damage sensitive circuitry.

The capacitance size of the DC blocking capacitor directly affects the signal truth by setting a cut-off frequency for the AC signal. High capacitance lets low-frequency signals pass. Low capacitance blocks more low-frequency wave content. So a wrong capacitance pick can bring twist or loss of the needed signal parts.

Capacitance must match the system block and wave range to make sure a low signal back and maximum power move. For example, in a 50 ohm system, send signals in the MHz range, pick the right size capacitor to make sure the block stays the same in signal way.

An improperly chosen capacitor can introduce either excessive impedance (causing attenuation of low frequencies) or insufficient filtering (leading to DC leakage). This makes accurate calculation based on bandwidth and impedance crucial during design.

Choosing the wrong DC blocking capacitor can result in serious performance issues. An undersized capacitor will attenuate or distort low-frequency components of the signal, potentially affecting synchronization signals or low-speed data.

On the other hand, a big capacitor may add no need cost, size, and bring high ESR. This hurts work at high waves. It may slow down the signal change due to more charge time.

In RF and analog paths, no match parts from wrong capacitance, block no match, or fill type can bring back, phase move, and full no steady. These hits show strong in exact systems like space talk or car radar sensors.

Selecting the ideal capacitance for DC blocking capacitors involves multiple design parameters. The most critical factor is the operating frequency range. For example, audio signals require larger capacitance values to pass lower frequencies (down to 20 Hz), whereas RF applications can use much smaller capacitors due to higher frequency operation.

Another important consideration is source and load impedance. Since the capacitor forms a high-pass filter with the surrounding circuit elements, both impedances influence the cutoff frequency. Designers must also consider acceptable insertion loss to ensure minimal impact on signal amplitude and integrity.

Required bandwidth plays a role as well. Wideband systems need carefully chosen capacitance that passes all required frequencies without distortion. In digital interfaces like USB or HDMI, tight timing margins necessitate exact capacitance matching for consistent performance.

In photovoltaic systems, DC blocking capacitors are used to block DC shift from solar panels but let the AC signal pass in measurement paths. They must stay steady in wide heat ranges from outside hits. Used in inverters of wind power and solar power, these capacitors help keep an exact system watch and control.

Wind turbine systems trust block capacitors to filter low-frequency noise from control signals. These capacitors must withstand wide voltage changes and fast spikes from the change in turbine run. Must handle wide voltage swings and transient spikes, stay needs to be here with long work life for low care in far spots.

In fast digital send systems like Ethernet and HDMI, DC blocking capacitors are set between links or in PCB lines to ensure a clean change and keep the signal true. These uses need tight allowance parts with low ESR and ESL to keep the wave shape and cut shake in gigabit data rates.

Same Series Resistance (ESR) stays a key point for DC blocking capacitors in signal uses. It sets how much energy is lost as heat during the run. Low ESR ensures low energy loss at high frequencies. These stays need to keep good and low heat push in power easy spots.

Low ESR cuts energy loss and heat at high frequencies. This makes it fit for RF talk systems or full pack PCBs where heat care matters.

The voltage rate must pass the maximum expected DC push in the capacitor to prevent it from breaking or dropping over time. Planners should add a safe space over the normal run voltage to count fast and old hits.

Fill item sets steadily in the heat change and old. C0G/NP0 fill gives great heat stability and is fit for exact analog or RF uses. X7R fill gives a small size with mid steady. This balances work and board space limits.

C0G/NP0 for stable capacitance over temperature ranges, and X7R for compact size with moderate stability requirements, are normal picks for use needs.

SMILER focuses only on capacitors with a strong look at signal truth answers for work, new energy, and talk markets. With full auto make lines, SMILER ensures high quality and exactness in manufacturing processes. State-of-the-art automated facilities ensure efficiency, precision, and consistency, optimizing production workflows and upholding stringent quality control standards. Ensure that the qualified rate of finished products is controlled above 99.93% on the basis of the daily production capacity of 300,000 products. This shows a great quality guard.

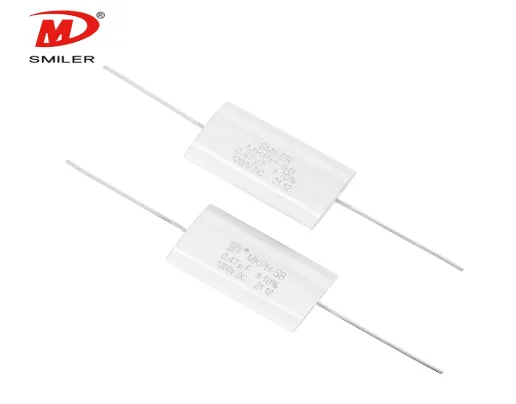

SMILER gives wide film capacitors fit for DC block uses with low ESR, high wave current hold power, and self-healing parts. These parts add to long life and high trust in hard spots like new energy systems or moving electric.

In solar inverter paths, SMILER's Film capacitors help filter no want DC but make sure exact watch of AC waves in change spot states. Low loss and low inside heat rise make them fit for outside sets where the heat change is big.

For wind turbines, SMILER capacitors join in talk control links where they must handle voltage fast and run safely over a long life. These sets gain from high steady, good self-healing power, and high trust. These key points cut care time in far spots.

A: Identify your signal frequency range and calculate the minimum required capacitance based on source/load impedance using the formula f_c = 1/(2πRC). Ensure that the voltage rating exceeds expected bias levels and choose dielectric types based on thermal stability needs.

A: C0G/NP0 offers excellent capacitance stability across temperature variations with low loss—ideal for RF or precision analog. X7R has higher permittivity, allowing smaller sizes but with moderate variation—suited for compact digital designs.

A: SMILER provides specialized film capacitors used in wind power and solar inverters with high reliability, self-healing properties, and long lifetime, making them a preferred choice for energy sector applications.

A: Yes. While it won't block desired frequencies, it may increase cost unnecessarily and introduce higher ESR or ESL, which affects performance at high speeds.

A: For Ethernet, prioritize tight tolerance, low ESR/ESL capacitors with stable performance over temperature. Ensure capacitance supports frequency range (typically >100 MHz) without introducing insertion loss or delay.

What Drives AC Capacitor Cost? A Comparison with DC Capacitors

Snubbing Capacitors in Power Electronics: RC vs. RCD Snubber

Understanding How DC Current in Capacitor Initiates Charging

Why DC Link Capacitance Matters in Modern Electronics Design?

Unveiling the Mechanics of Snubber Condensator in Power Systems