Bidirectional capacitors are vital for non-polarized circuit designs. They allow current to flow evenly in both directions. This is key for alternating current (AC) and signal-based systems. Their ability to work consistently, no matter the voltage direction, makes them perfect for circuits with frequent polarity shifts.

In today's electronics, especially with AC signal handling and small modular setups, managing reverse voltages without damage is a core need. Unlike polarized capacitors, like electrolytics, bidirectional capacitors need no specific orientation during setup. This simplifies design and lowers the chance of errors from wrong placement.

Symmetrical capacitance from bidirectional capacitors ensures balanced energy storage and release at both ends. This helps circuits with frequent voltage changes, such as audio amplifiers or sensor interfaces.

In non-polarized setups, this even capacitance keeps signals clear without causing phase shifts or odd behaviors. This steady performance across polarities boosts system reliability. It also supports consistent results in changing electrical conditions.

Traditional polarized capacitors face issues in non-polarized tasks. They can wear out or fail under reverse polarity. This leads to lower dependability and more upkeep. Their need for correct orientation also complicates assembly. It raises the risk of human mistakes.

Bidirectional capacitors fix these problems by removing polarity concerns. They offer low equivalent series resistance (ESR), strong heat stability, and small sizes. With advances in power electronics, converter technology grows smarter, more modular, and smaller. These trends match the strengths of bidirectional capacitors. They support smaller, modular designs well.

In AC circuits, voltages switch between positive and negative cycles. Bidirectional capacitors handle these shifts without losing performance or taking damage. Their non-polar nature lets them charge and discharge well, no matter the voltage direction.

This makes them great as AC Filter Capacitor components. They smooth out voltage ripples and reduce noise. Their steady capacitance over a wide frequency range ensures reliable filtering in power supplies and signal lines.

Signal clarity is crucial in audio and communication systems. Any unevenness or distortion from parts can harm sound quality or data accuracy. Bidirectional capacitors provide clean signal paths. They offer a steady response across different frequencies and voltages.

For instance, in audio crossover networks or RF circuits, these capacitors keep waveforms true. They prevent phase distortion and ensure low resistance paths for high-frequency signals.

Sensor modules often face quick-changing conditions. This leads to sudden voltage spikes or drops. Bidirectional capacitors steady these changes by taking in and releasing energy as needed.

Bus capacitors help balance voltage swings. They store and release energy to keep power systems stable. When used in sensors or control units, this steadying effect cuts error rates. It also boosts system response.

Bidirectional capacitors are common in small consumer electronics. Their space-saving design and steady performance suit devices with changing conditions.

In battery-powered devices like smartwatches or wireless earbuds, keeping energy balanced is key to long life. Bidirectional capacitors manage power surges during charging or discharging. They act as a buffer to smooth current flow.

The module capacitor uses an integrated packaging design. It combines the battery cell and laminated busbar welding. This offers low cost, small size, small capacitance value, high current, low ESR, low inductance, high integration, and custom options. These traits make them ideal for wearables where space is tight but performance needs are high.

Small size drives electronics design today. Bidirectional capacitors offer strong performance in tiny packages. Their non-polar nature also simplifies PCB layout. This allows better use of board space.

In industrial settings, reliability under stress is a must. Bidirectional capacitors give solid performance even in high-frequency switching setups common in automation systems.

Industrial converters often work at high switching speeds. Traditional electrolytic capacitors may fail due to heat or ESR limits. After capacity drops, film capacitors can replace electrolytics as split capacitors. This helps extend inverter life. Film-based bidirectional capacitors offer better heat endurance and longer working life in such conditions.

Electromagnetic interference (EMI) is a big issue in dense electrical setups. Bidirectional capacitors reduce EMI by offering low-resistance paths. These shunt high-frequency noise away from sensitive parts. This boosts overall system EMC compliance without needing bulky shielding.

At SMILER, we focus on precise capacitor design, new materials, and long-term dependability. Our bidirectional capacitor series shows this approach. It delivers steady performance across many uses.

We stress even capacitance behavior, low ESR, heat stability, and small packaging. These are key for modern circuit needs.

SMILER's bidirectional capacitor solutions cover a wide range of rated voltages. They suit both low-voltage signal circuits and higher-voltage industrial modules. With tight capacitance tolerances (often ±5% or better), designers can count on steady performance across batches.

Heat stability is a core strength. Our products keep stable capacitance values across wide temperature ranges (-40°C to +125°C). This ensures reliable work in tough conditions.

We use advanced dielectric materials like metallized polypropylene films. These offer great self-healing and resist dielectric breakdown. With strict lifecycle testing, SMILER’s capacitors meet tough global standards for safety and long life.

A recent IoT gateway project needed ultra-low ESR bus decoupling in a small space. Engineers chose SMILER's compact bidirectional film capacitor module. It steadied voltage rails during load changes. This improved power conversion efficiency and cut ripple noise. These factors greatly extended device uptime.

In an automotive ECU task with analog sensor signals prone to interference, SMILER's symmetric-capacitance solution was used in a signal conditioning stage. It's low inductance, cuts phase distortion. It also boosted EMI immunity. This ensured accurate sensor readings, even during engine startup surges.

A: A bidirectional capacitor works in circuits where voltage direction changes often, like AC signal lines or audio paths. It gives even capacitance regardless of direction. This ensures reliable energy storage and filtering without orientation limits.

A: Pick based on your task needs. Consider voltage rating, capacitance value, ESR needs, heat range, and size. For precise tasks or harsh settings, film-based options like SMILER's offer top performance.

A: They suit non-polarized tasks, like AC circuits or signal coupling, where polarity shifts are common. Polarized capacitors may give higher capacitance per volume, but they can't handle reverse voltages safely.

A: SMILER provides well-crafted bidirectional capacitor solutions. They feature low ESR, tight tolerance control, and heat stability up to 125°C. They meet long-term reliability standards for industrial-grade uses.

A: Yes, especially in AC filtering or decoupling roles where polarity sensitivity is a risk. Film-based bidirectional types often give longer life and better high-frequency performance than electrolytics.

Key Applications of Energy Storage Inverters in Industrial Operations

AC to DC Filter Circuit Design: Essential Considerations for Experts

How Do Capacitors Improve Efficiency in Medium Voltage Inverters?

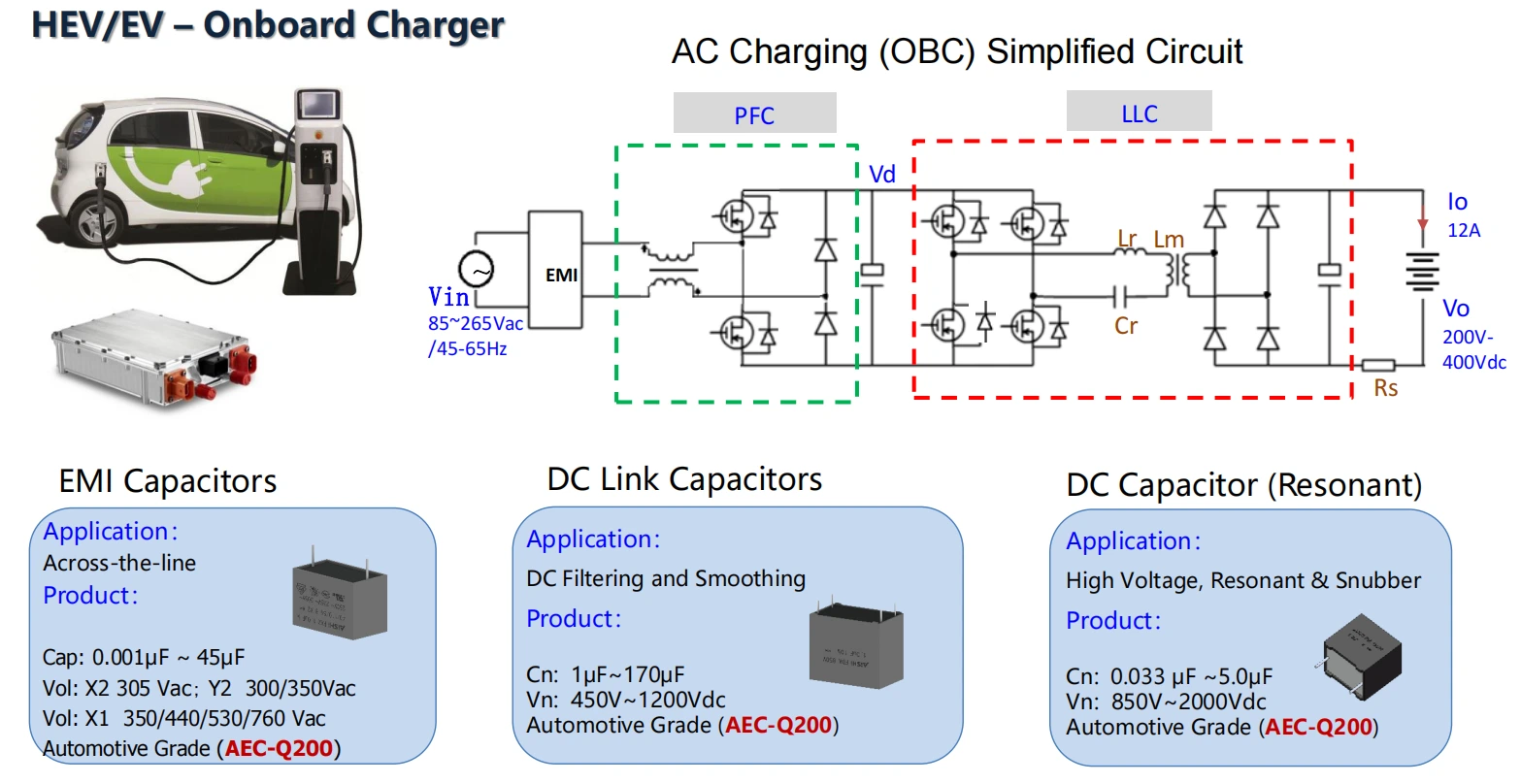

How Do Capacitors Boost Onboard Charger Performance in EV Systems?

Electric Vehicle Fast Charging Station: How Capacitors Improve DC Link Stability