Voltage spikes and high dV/dt transients make snubber capacitors essential components in modern power switching circuits. When MOSFETs or IGBTs turn on or off, parasitic inductances in leads, PCB traces, and transformer leakage cause sharp voltage overshoot. These spikes accelerate semiconductor stress, increase switching losses, and reduce long-term device reliability. Snubber capacitors absorb this excess energy at the moment of transition, helping stabilize the switching waveform and protect the semiconductor junction.

The main traits of snubber capacitors, such as low ESR, low ESL, strong pulse-current handling, and solid dV/dt resistance, shape switching results. Low ESR cuts down on self-heating issues. Meanwhile, low ESL lessens the chance of ringing in areas with high dI/dt. The ability to handle high pulse currents lets these capacitors endure repeated surge events. Such events are common in tough-switching converters. Good dV/dt strength guards the dielectric during sharp changes in SiC/GaN-based circuits. This leads to longer working lives.

Film snubber capacitors are widely used in high-frequency and high-power circuits because of their stable electrical behavior and excellent self-healing properties. Metallized polypropylene film offers a fast charge-discharge response, low dissipation factor, and robust thermal endurance. In welders, renewable-energy inverters, EV chargers, and motor drive systems, film snubber capacitors provide stable operation under repetitive transients and sustained high-frequency stress.

RC snubber capacitor setups work by releasing switching energy via a resistor-capacitor pair. Engineers place this pair right across the switching device. At turn-off, the capacitor soaks up the voltage spike. Then, the resistor slowly turns that stored energy into heat. This damping process cuts back on ringing. It also lowers EMI output and stops too much voltage strain.

RC snubber capacitors do a good job at curbing ringing and cutting EMI in MOSFET and IGBT uses. High-frequency ringing can spread through cables and ground paths. This often causes issues in nearby circuits. RC snubbers smooth out switching edges and catch stray energy. Because of this, converters meet EMC rules more easily. Such rules apply to lighting drivers, small-motor controllers, and helper power units.

Picking R and C values for an RC snubber calls for a grasp of resonant frequency, damping needs, and heat limits. If the capacitor is too big, it boosts switching losses. On the other hand, one that is too small might fail to control ringing well. The resistor has to offer enough damping. Yet, it should not overheat. Designers usually check the circuit's resonant frequency. They then tweak the RC time constant to better handle transients.

Real-world limits show up when using RC snubbers in high-energy switching spots. The resistor keeps releasing energy all the time. So, RC snubbers lose efficiency at bigger power levels. In setups like industrial inverters, big power supplies, and transformer-based converters, the energy each cycle might go beyond the resistor's safe heat point. These issues often push designers toward RCD snubber designs. Such designs fit better for high-voltage or high-power converters.

RCD snubber setups add a diode to form a one-way clamping route. This setup makes sure the capacitor charges only during set switching times. It allows tighter voltage control. At the same time, it avoids steady resistor energy loss. The diode directs spike energy to the snubber capacitor. After that, the resistor lets it out safely.

Energy recovery gives RCD snubbers an edge over RC types in heavy-load situations. They skip ongoing energy release. This cuts heat buildup and boosts heat steadiness. Such gains help in systems like high-voltage flyback converters, EV chargers, and industrial inverter bridges. There, switching energy plays a big role in performance.

Choosing the snubber capacitor and diode matters a lot in fast-repeating switching areas. The capacitor needs to stand up to repeated surge currents and high dV/dt rates. The diode requires quick recovery and low reverse charge. In SMPS controllers, motor-drive inverters, and high-frequency converters, top film capacitors and fast diodes build solid RCD networks. They ensure dependable work over time.

Designers pick RCD snubbers when switching energy runs high. They also choose them if voltage overshoot demands close watch or if converter efficiency needs a lift. RC snubbers fit low-power or budget-friendly tasks. There, energy per cycle stays small. The decision hinges on switching energy, heat boundaries, clamping needs, and EMI rules.

Voltage clamping precision varies between RC and RCD snubber capacitors. This comes from their basic structures. RC snubbers give broad damping. However, they cannot hold the peak voltage tightly. RCD snubbers enable sharper clamping. This makes them a good match for high-voltage converters and uses that need stricter safety buffers.

Heat handling stands out as a key factor when looking at snubber capacitor types. RC snubbers face steady energy release through the resistor. This raises system losses at higher speeds. RCD snubbers lower switching losses. They do this by holding and letting out energy in a managed way. As a result, they provide better heat efficiency in quick switching rounds.

How well EMI suppression works differs between RC and RCD snubber capacitors. RC snubbers offer better high-frequency damping. This stems from their resistive nature. RCD setups cap peak voltage. Yet, they might need fine-tuned layouts to dodge noise pickup. Solid PCB design plays a big role. It includes short loops, cut-down stray inductance, and right grounding. These steps matter for both snubber types.

The right fit for applications decides if RC or RCD snubber capacitors work best in SMPS, DC-DC converters, or motor-drive systems. RC snubbers find common use in helper supplies, lighting drivers, and small converters. RCD snubbers shine in motor drives, high-power SMPS parts, welding inverters, and high-voltage flyback circuits. In those, energy levels rise, and keeping efficiency counts.

Deciding between RC and RCD snubber capacitors means checking the circuit's voltage, current flow, load kind, and switching rate. RC networks bring ease and lower costs. RCD networks boost efficiency in high-energy or fast-switching designs. Knowing the switching patterns helps match capacitor traits to what the system needs.

The main points for picking high-pulse snubber capacitors cover peak-current strength, dV/dt resistance, ESR/ESL traits, and heat stability. Film capacitors built for snubber tasks must handle repeated high-current bursts. They should not break down. Structures with low inductance improve how well they handle transients.

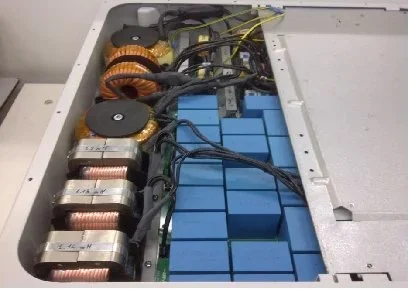

SMILER capacitor supplies film capacitors that see broad use in industrial snubber tasks. They stand out due to low ESR, low ESL, and firm surge-current handling. The metallized polypropylene build gives steady electrical action during fast switching shifts. This aids designers in keeping even clamping results, even under heavy heat pressure. In actual inverter and motor-drive projects, SMILER capacitor has shown strong dV/dt steadiness. This lets gear run well under repeated transient loads. These features make them a solid choice for tough setups where dependability and long service matter most.

Optimizing the layout boosts how well snubber capacitors perform. Place snubber parts near switching devices. This cuts parasitic inductance. Wide copper traces help lower resistive drops. A smart layout ensures quick energy pickup during switching shifts. It also strengthens the whole converter's steadiness.

SMILER capacitor brings forward manufacturing strengths backed by automated lines, tight quality checks, and global certifications. With ISO9001, VDE, TUV, UL, CE, and CQC approvals, SMILER capacitor guarantees steady film capacitor work across fields like renewable energy, power conversion, and automation.

SMILER capacitor's snubber capacitor lineup features the MKPH-S series. It targets surge pickup in IGBT buffer circuits. The MKPH-LS series fits high-frequency, high-current tasks. These items show low inductance, low ESR, and high pulse strength. They work well in inverter welders, UPS systems, photovoltaic inverters, and motor-drive circuits.

Key product strengths, like high dV/dt handling, solid peak-current resistance, and great self-healing traits, ensure SMILER capacitor Snubber Capacitors offer steady long-run operation. Their tough build lets them face ongoing high-frequency switching and rough surroundings. This supports reliable work in industrial and renewable-energy power systems.

A: Selecting the right snubber capacitor requires evaluating voltage stress, switching frequency, transient energy, and dV/dt requirements. Film capacitors from SMILER capacitor with strong pulse endurance and low ESR are ideal for industrial switching systems.

A: Snubber capacitors reduce voltage spikes, suppress ringing, lower EMI, and improve semiconductor reliability. High-quality film snubber capacitors ensure stable switching behavior and longer converter lifespan.

A: RCD snubber capacitors offer higher efficiency and better control of peak voltage in high-energy designs, while RC snubbers provide simple damping in lower-power converters. The choice depends on switching energy and design goals.

A: A high-pulse snubber capacitor should offer high dV/dt capability, low ESR/ESL, high peak-current endurance, and stable dielectric behavior across a wide temperature range.

A: Film snubber capacitors provide low loss, fast response, strong surge endurance, and excellent long-term stability, making them reliable for demanding applications such as motor drives, welders, and inverters.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Understanding DC Capacitance to Prevent Converter Oscillations

Analyzing Resistor and Capacitor in Parallel for DC Circuit Optimization

Unveiling the Mechanics of Snubber Condensator in Power Systems

Exploring Capacitor in DC Analysis: Practical Circuit Insights