The main difference between an RCD snubber and an RC snubber lies in their components and how they handle energy. An RC snubber uses a resistor and a capacitor connected in series. It absorbs voltage spikes by turning switching energy into heat within the resistor. On the other hand, an RCD snubber includes a diode alongside the resistor and capacitor. This allows it to redirect energy through a separate path or store it.

The diode in an RCD snubber improves energy handling, especially in circuits with inductive loads, like those protecting IGBTs. It permits one-way current flow. This reduces energy loss during repeated switching. As a result, RCD snubbers are often chosen for applications needing efficient power use and better heat management.

RC snubbers focus on reducing high-frequency noise from stray inductance and capacitance in switching devices. They work like low-pass filters. This smooths out fast voltage changes that could cause electromagnetic interference (EMI).

On the contrary, RCD snubbers perform better in restricting large voltage spikes as a result of inductive kickback. The diode enables the capacitor to release trapped energy along a defined resistive path upon switch deactivation. This works to contain high voltages within sensitive devices like IGBTs or MOSFETs.

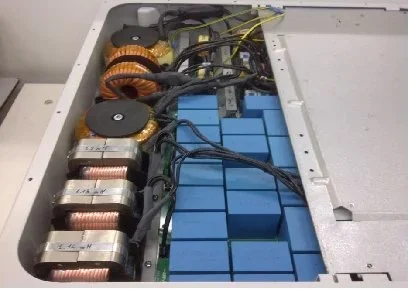

The MKPH-S Snubber capacitor, which is employed in IGBT buffer circuits, proves that the right snubber must be chosen for efficient transient management.

In real-world setups, an RC snubber is placed directly across a switch's terminals, such as the collector-emitter of an IGBT. Its simple two-part design is easy to use. However, it may cause ongoing energy loss during operation.

RCD snubbers position a capacitor across the switch, with a resistor-diode branch to release stored energy during switching. This setup cuts down on continuous losses. It also provides strong protection against high voltages.

Capacitors are vital in both RCD and RC snubbers. They capture voltage spikes during switching events. Without proper management, these spikes can harm semiconductors or increase EMI.

In both designs, capacitors briefly hold extra energy. They release it as heat through resistors or via controlled paths through diodes. Their fast response to voltage changes makes them essential in high-speed switching systems.

Picking the correct capacitance value is key to keeping circuits stable. Too small a value may not control spikes well. Too large a value could slow switching or stress components.

Designers choose capacitance based on factors like operating frequency, transient energy, and acceptable voltage ripple. They often use simulation tools and testing to adjust these values for the best results.

Snubber circuit capacitors require voltage ratings many times above peak expected voltages. They're this way to last longer and not break down when there are surges.

Rated voltage (VR) 85℃ 700VDC ~ 3000VDC of capacitors like in the MKPH-S series shows that they are meant for industrial high-voltage applications.

An RCD snubber works best with inductive loads that create large voltage spikes, such as in motor drives or inverters. The diode's energy recovery reduces heat stress. This makes it more efficient than an RC snubber in these cases.

Applications needing precise energy control, like high-power IGBT modules, benefit greatly from RCD snubbers. They reduce thermal strain on components.

RC snubbers are ideal for handling fast-switching noise rather than large energy surges. They are common in low- to medium-power circuits, such as relay contacts or small SMPS designs. Simplicity matters more than efficiency in these cases.

Their small size and ease of use make RC snubbers a good choice when EMI reduction is the main goal.

RCD snubbers perform better in tough conditions but are more complex due to the added diode. This can raise design time and costs.

RC snubbers are simpler and cheaper. However, they have higher ongoing losses and are less effective at controlling spikes in heavy inductive loads. Designers must balance these factors based on system needs, budget, and heat concerns.

In switch-mode power supplies (SMPS), both RC and RCD snubbers are critical, depending on the circuit. Application: Snubber, IGBT Protection highlights their role in shielding switches from transient stress. They also boost efficiency by reducing ringing losses.

Motor drives involve frequent high-current switching. This can create notable EMI if not controlled. Properly designed RC or RCD snubbers lower noise and protect gate drivers from voltage damage. This extends the equipment's lifespan.

Inverters working at high frequencies need strong transient control due to fast voltage changes. DC Filtering and Smoothing Snubber, IGBT Protection shows how capacitors in these circuits maintain signal quality under varying loads.

SMILER specializes in advanced capacitor solutions for power electronics. These include DC link filtering, resonant circuits, AC filtering, and snubbing for RC and RCD setups.

Our focus is on reliable performance through innovative materials and strict quality standards, such as GB/T 17702-2021 (IEC 61071:2007).

SMILER's capacitors offer high pulse strength, good self-healing, and excellent flame resistance. They are highly reliable and have a long lifespan. These traits make them ideal for tough environments with frequent switching or high temperatures up to +105°C.

Low Equivalent Series Resistance (ESR) reduces heat during operation. High pulse strength allows capacitors to handle sharp transients without wear. These qualities are crucial for RC damping and RCD energy-absorbing circuits.

SMILER's MKPH-S series provides flexible mounting options (M6/M8). They come in various sizes and specifications to fit different designs. This makes them suitable for both simple RC filters and complex RCD clamp circuits.

In manufacturing lines with servo motors and IGBT modules, SMILER’s capacitors are used in custom RCD snubbers. They reduce downtime from component failure and manage heat effectively.

Solar inverters face wide temperature changes and varying loads. SMILER's polypropylene film capacitors perform reliably in both RC input filters and RCD output clamps. This ensures stable inverter performance over time.

EV traction systems need compact, robust electronics for high voltages. SMILER's low-ESR capacitors in RC noise filters and RCD transient clamps improve resilience against grid disturbances during charging.

A: An RC snubber uses a resistor-capacitor pair to dampen transients. An RCD snubber adds a diode for more efficient energy redirection. This makes it better for inductive loads like motors.

A: Choose an RC snubber for EMI suppression in simpler circuits. Use an RCD snubber for efficient control of high-energy spikes in inductive setups like IGBTs or relays.

A: SMILER provides specialized capacitors with high pulse strength, self-healing, and low ESR. These are ideal for effective RCD snubber performance.

A: Start with values like 100nF–1µF. Final values depend on circuit specifics, like switching frequency, load type, and peak voltages. Use simulation and testing to confirm.

A: They are used in motor drives, industrial automation, and solar inverters. RCD snubbers control inductive kickbacks while maintaining efficiency through controlled energy paths.

Why DC Link Capacitance Matters in Modern Electronics Design?

Analyzing Resistor and Capacitor in Parallel for DC Circuit Optimization

Unveiling the Mechanics of Snubber Condensator in Power Systems

Exploring Capacitor in DC Analysis: Practical Circuit Insights

Mastering the Reset of Your CBB61 Fan Switch