Outdoor capacitors are built to tough it out in wild conditions. They face rain, snow, dust, salt fog, and crazy temperature swings. These can wreck parts fast if not handled right. Vibrations and pollution from factories or cars add more stress. Unlike indoor capacitors, which chill in cozy enclosures, outdoor ones brave the elements head-on. That makes toughness a must.

To stand up to nature's punches, outdoor capacitors use special materials. Housings are often UV-stabilized plastic or metal with anti-rust coatings. Inside, components get sealed in resin to block water and stay steady. The capacitor features a metallized polypropylene film for its internal structure, a plastic shell for packaging, and resin filling with UL94 V-0 rating, ensuring reliable performance in all conditions.

Weatherproofing is a big deal. Moisture or UV rays can mess up insulation or dielectrics, causing short circuits or wonky capacitance. High humidity might spark partial discharges if the seal isn't tight. The products offer excellent features with high resistance to humidity. Outdoor capacitors need to keep their cool through years of sun, rain, or whatever else comes their way.

The dielectric is the heart of a capacitor's grit. For outdoor use, metallized polypropylene film is a top pick. It's got low losses and strong insulation. Plus, it stays steady across a wide temperature range. The capacitor uses metallized polypropylene film as its medium. This makes it perfect for rough settings where performance can't falter.

Hot summers and freezing winters can mess with capacitor materials. Temperature swings tweak their size and dielectric constants. That can shift capacitance if not planned for. Operating temperature range (case) Max. operating temperature, Top +105℃ Lower category temperature Tmin -40℃. Manufacturers use tricks like derating—For temperatures between 85 °C and 105 °C, 1.33%/°C of Vop derating compared to VR at 85 °C—to keep things stable.

Water sneaking in is a top capacitor killer. Resin potting seals parts tightly against moisture while helping with heat control. UV-resistant shells fend off sun damage over long hauls. In salty coastal spots or smoky industrial zones, anti-corrosion coatings on terminals and enclosures keep things running smoothly.

Outdoor capacitors are MVPs in power grids. They help regulate voltage and balance reactive power on utility poles or substations. Their ability to handle wild loads and shrug off environmental wear makes them key for steady grids.

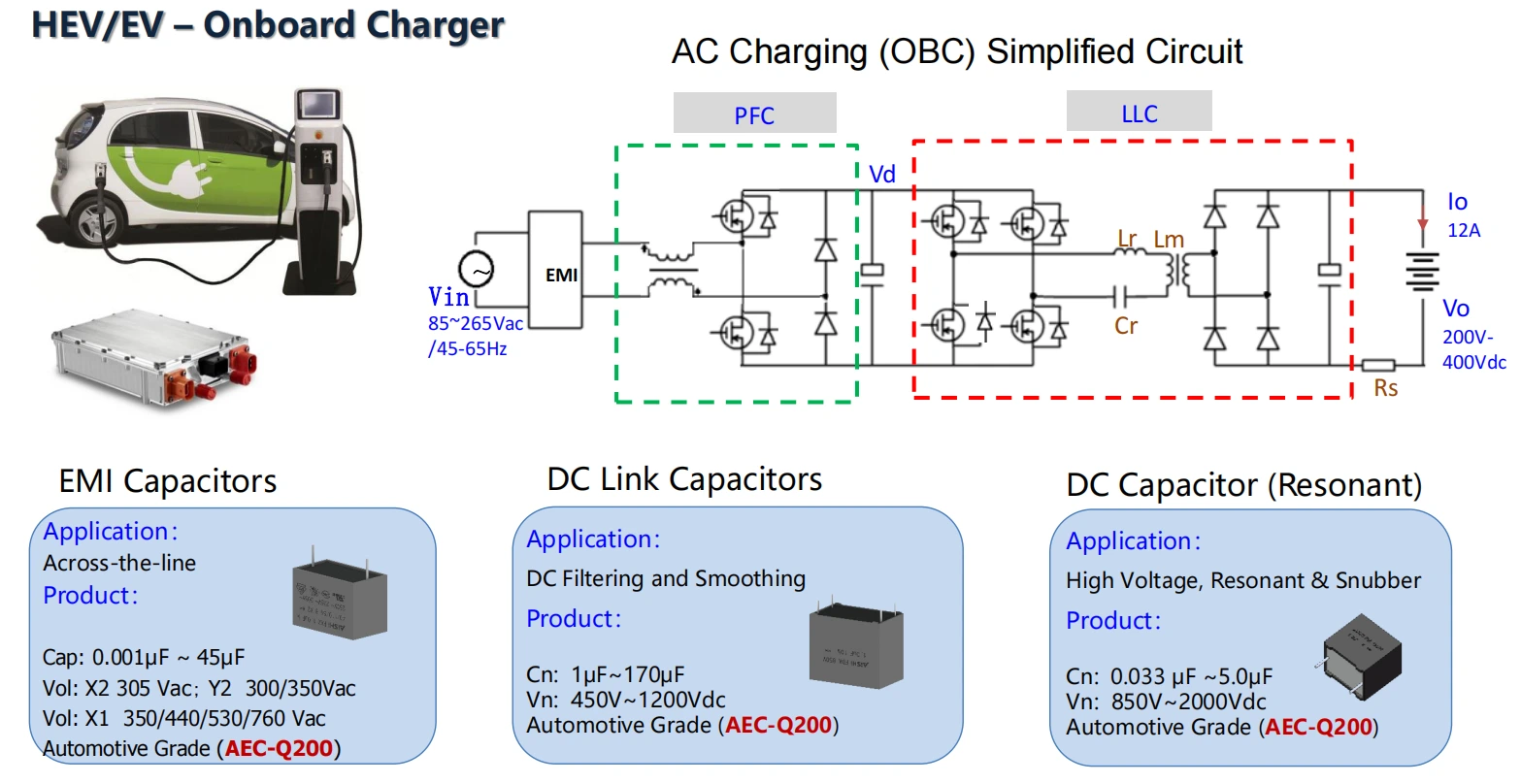

In wind turbines or solar farms—often stuck in remote, exposed spots—outdoor capacitors smooth inverter outputs and handle DC link filtering. This capacitors are ideal for applications such as frequency converters, industrial and high-end power supplies, automobile DC-DC systems, and solar inverters. Their tough build keeps energy flowing despite changing weather.

For example, a solar farm in northern Europe used outdoor-rated DC link capacitors with resin encapsulation. These stayed solid through snowy winters and sub-zero chills, keeping inverters humming.

Capacitors in HVAC units or remote control panels face rain, dust, and frost year-round. They handle motor start/run tasks and EMI suppression under shifting loads. Their rugged design ensures they keep going strong.

Smart city gear like streetlights, traffic signals, or EV chargers needs compact, tough capacitors. These handle power conditioning in pole-mounted or street-side setups, battling urban grime and weather with ease.

Spot-on capacitance keeps systems tuned just right. Whether filtering inverter harmonics or balancing power lines, accuracy prevents issues like motor overheating or unstable voltage. Environmental stress can cause drift, shortening gear lifespan if you skimp on quality.

Outdoor capacitors face unique risks. Moisture can zap dielectrics, causing breakdowns. Salt spray corrodes terminals. Thermal cycling might swell parts. UV light can age polymers, dropping capacitance. Modern film capacitors with self-healing properties dodge some of these by isolating small faults. High reliability, self-healing property.

Outdoor setups—like mountaintop wind farms or offshore platforms—are tough to service. Long-lasting capacitors cut down on pricey field trips. Designs with extended lifetimes mean less hassle and cost. Long lifetime.

SMILER crafts outdoor capacitors for the toughest spots. We use cutting-edge materials and strict testing to ensure they shine in the field.

Our high-performance resin potting and hermetic seals block water while handling heat during heavy loads. They keep capacitors humming through wild weather swings.

We use top-notch metallized polypropylene films for low ESR and minimal drift. Their self-healing traits ensure steady performance over the long haul, no matter the conditions.

SMILER offers a range of rated voltages for all kinds of projects, from low-voltage solar arrays to high-voltage grids. Rated voltage (VR) 85℃ 500VDC/600VDC/800VDC/900VDC/1000VDC 1100VDC/1200VDC tailored to your needs. In a desert solar plant with 40°C daily swings, our custom DC link capacitors ran flawlessly for two seasons, proving their grit.

Q: What is an outdoor capacitor used for?

A: Outdoor capacitors work in exposed electrical systems like power grids, solar plants, HVAC units, EV chargers, and streetlights, where weatherproofing is key.

Q: How does weather affect capacitor performance?

A: Humidity, UV rays, and temperature swings can harm dielectrics, causing capacitance loss or failure if not properly shielded.

Q: What makes polypropylene film suitable for outdoor capacitors?

A: It's got great insulation, thermal stability, and self-healing powers, perfect for tough outdoor conditions.

Q: Can standard indoor capacitors be used outdoors with enclosures?

A: Enclosures help, but indoor capacitors lack the sealing needed for long-term exposure. Outdoor-grade ones are the safer bet.

Q: How do I choose the right voltage rating for an outdoor capacitor?

A: Pick a rating above your system's peak voltage, factoring in transients and derating for high temperatures.

Exploring the Role of DC Link Capacitor Use in EV Power Systems

Application of DC-Link Capacitors in EV Fast Chargers

Understanding the Use of DC Link Capacitor in Inverter Design for EVs

How to Choose the Best Bus Capacitor for Your EV Inverter Needs

How Do Capacitors Boost Onboard Charger Performance in EV Systems?