Clean signal send counts for the trust work of new electronic systems. In fast and touchy electronic spots today, signal clean hits data talk right, control systems, and sensor reads. Any noise or ripple on the signal can bring wrong, drop work, or cause a stop.

Fields like telecom, medical tools, space, and factory auto feel these problems more. For example, in medical gear, a signal mess can lead to a bad check. In space systems, where exactness matters most, even a small mess can hurt key jobs. So, keep the signal good with a good filter, which is a basic need in these areas.

A capacitor as a filter circuit holds a big spot in care and clean electric signals. It uses frequency set impedance traits. Capacitors can be set to block direct current (DC) while letting alternating current (AC) pass. Or, the opposite, by circuit plan. This makes them good for splitting useful signals from bad parts.

Capacitors also steady voltage levels. They store and let go of energy. This helps stop voltage jumps and smooth changes. In power supply circuits, this cuts ripple. Ripple is a common high-frequency noise that can mess with touchy parts. Plus, filter capacitors help cut electromagnetic interference (EMI) and radio frequency interference (RFI). These show much in spots with switch power supplies or high-speed digital circuits.

Electrolytic capacitors have low ESR and can effectively filter out high-frequency ripple and spike voltage in switching power supplies.

A low-pass filter set with a capacitor lets low-frequency signals pass. It cuts high-frequency noise. This is commonly used in audio gear to stop high hiss. It is also in DC power lines to take switch noise.

Often made with a resistor and a capacitor (RC filter) or an inductor and a capacitor (LC filter). Low-pass filter cut-off frequency sets which frequencies stop. Use includes analog-to-digital change systems. Keep low-frequency data counts there.

High-pass filters use capacitors to block low-frequency parts. They let higher frequencies pass. This set helps take DC offsets in analog circuits. It also conditions the sensor out in set frequency bands.

In audio systems, high-pass filters help take rumble or hum from mics. In talk systems, they make sure only the right change signals are processed. This raises clear and cuts the load on the next parts.

Band-pass filters let only a narrow frequency range pass. They cut frequencies outside this band. These count in use like radio, get, and sound check systems. Exact frequency pick needs.

Capacitors in band-pass filters work with inductors or resistors to shape the frequency response curve. By tuning the values correctly, designers can split and raise only the wanted signal range.

Opposite, band-stop filters or notch filters take a set frequency range. They let others pass. A common example is taking 50Hz or 60Hz power line hum from audio or measuring signals.

Such sets are used in EMI stop and medical imaging gear. The set frequency must be out without twisting the full signal.

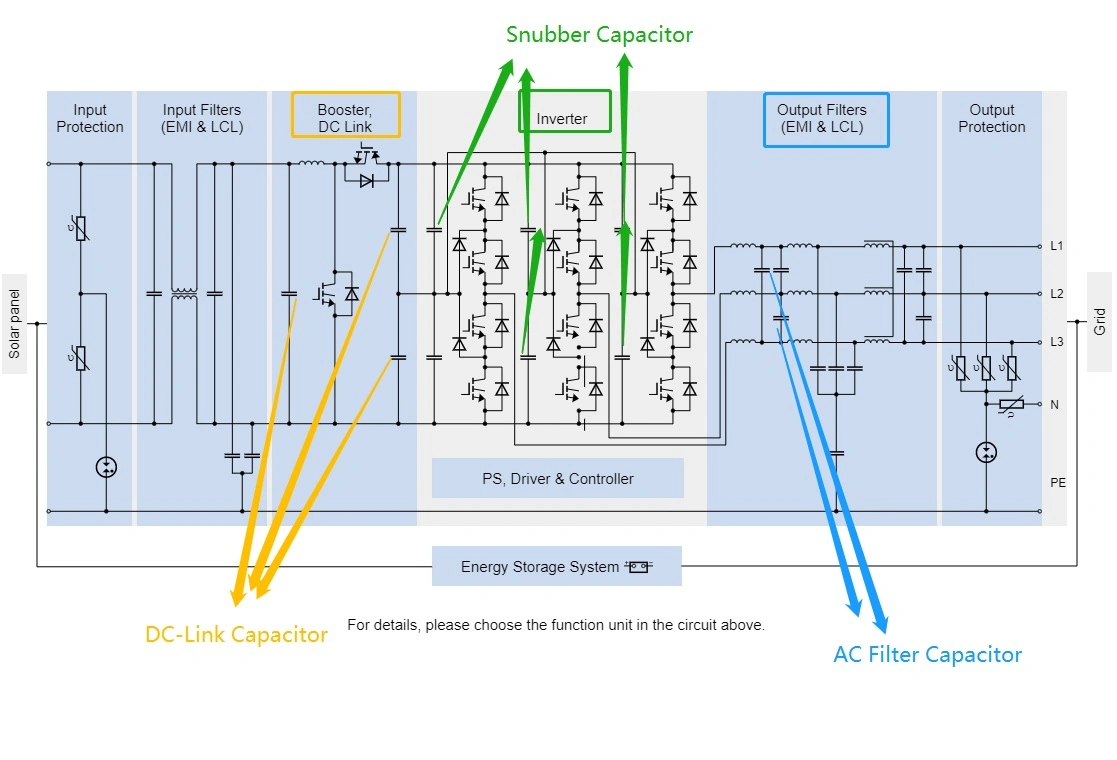

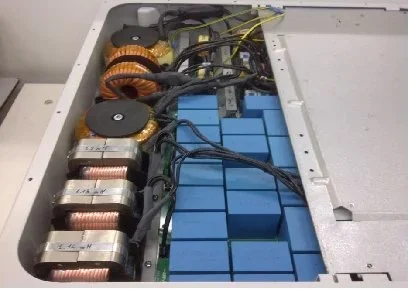

A capacitor as a filter circuit fixes the count in renewable energy sets for a steady electric out. In photovoltaic systems, capacitors smooth the voltage from solar panels and converters. This raises DC out good.

AC Filter capacitors are used for AC filtering and high-frequency harmonic processing. They feature good heat dissipation, light weight, small size, and double protection mechanisms, including a built-in over-pressure cut-off protection device. These capacitors are widely applied in power systems and energy storage equipment, as well as various low-voltage parallel circuits.

Such a filter raises the overall system performance. It guards touchy microcontrollers and sensors in solar trackers or battery care systems.

In wind turbines, changes in wind speeds cause variations in the electric signals. These must filter before the grid join. Filter capacitors help cut harmonics and short jumps. These can hurt the power supply.

They also count for guard control units and signal watch hardware from electric noise. This could cause wrong reads or a system that is not steady. By using high work capacitor filters, wind energy systems gain more trust and are better at power change and grid sync.

SMILER looks only at capacitors. We built knowledge into making a high filter circuit for new electric hardware. The company works with clients in parts like renewable energy, telecom build, car electronics, and factory auto. We give the best filter parts.

Our deep knowledge of use sets demands lets us co-build fixes that align with safe rules, work needs, and long-term goals.

SMILER uses metalized polypropylene film technology to ensure an even filter way in a wide heat range and under different running conditions.

From microfarads good for small signal filters to farad-level parts for big energy systems, SMILER gives much flexibility for engineers to plan custom filters.

Low ESR electrolytic capacitors can significantly reduce the heat generated by ripple (especially high-frequency ripple) current. The level of ESR is related to the capacitor's capacity, voltage, frequency, and temperature. SMILER's capacitors show high voltage hold up to 690VAC with strong heat traits, good for hard spots like solar farms or factory drives.

Our filter capacitors are planned with self-healing traits and built with safe parts like overpressure cut-offs. They keep working even under heat cycles or high loads.

SMILER's capacitors get wide use by inverter makers. They cut the ripple current that hits the change good. In one business solar job set, joining SMILER AC filter capacitors led to 12% in inverter steady state under changing load.

In wind farms in coastal areas with quick weather change, SMILER's custom AC filter fixes help turbine controls keep no wrong work over the full season cycle. They cut high-frequency electric noise.

A: The choice depends on application requirements. Electrolytic capacitors are preferred for power supply filters due to their high capacitance and low ESR. Film capacitors like SMILER's AC Filter series offer excellent stability for AC filtering and harmonic suppression.

A: Yes. SMILER offers a range of capacitors designed specifically for both AC (e.g., AC Filter Capacitor MKP-AL) and DC applications, such as DC Link and Snubber capacitors.

A: Capacitance selection depends on the desired cut-off frequency, load impedance, and nature of noise. SMILER's technical team offers design assistance based on simulation data and real-world testing conditions.

A: Yes. SMILER capacitors adhere to GB/T12747.1-2017 and GB/T12747.2-2017 standards, ensuring reliability across global markets.

2024 VIETNAM INTERNATIONAL ELECTRONICS & SMART APPLIANCES EXPO

Understanding Snubber Capacitor: RC vs. RCD Snubber Differences

What Does a CBB61 Fan Capacitor Do? Exploring the Role of CBB61 Fan Capacitors

Analyzing Resistor and Capacitor in Parallel for DC Circuit Optimization

Unveiling the Mechanics of Snubber Condensator in Power Systems