RCD snubber capacitors play a critical role in addressing EMI challenges that increasingly define modern power electronics systems. As switching frequencies rise and semiconductor devices move toward faster edge rates, unwanted electromagnetic interference becomes harder to control using only downstream filtering. In many converters, EMI originates directly from switching transients rather than from load-side disturbances.

EMI issues in power electronics are no longer limited to regulatory compliance concerns. Excessive noise often leads to false triggering, communication instability, premature component aging, and unpredictable system behavior. For engineers designing SMPS, inverters, or DC-DC converters, suppressing EMI at its source has become a core design objective rather than a secondary optimization step.

High-frequency switching circuits generate EMI primarily due to parasitic inductance interacting with rapid voltage transitions. When a MOSFET or IGBT turns off, the stored energy in leakage inductance forces the voltage to rise sharply, creating high dv/dt conditions. These fast transitions excite resonant circuits formed by stray inductance and capacitance.

Ringing from these parasitics makes wideband noise. This noise can spread or travel through power and signal lines. Such EMI proves hard to cut down once it moves across the PCB or enclosure. Switching speeds keep rising. So, usual layout tweaks alone often fail to handle ringing-caused EMI.

Voltage overshoot in hard switching adds a lot to EMI creation. When energy in leakage inductance lacks a place to go, it causes sharp voltage peaks across the switching device. These peaks boost electromagnetic emissions. At the same time, they strain semiconductor junctions.

Ongoing contact with voltage overshoot harms EMI results. It also speeds up device breakdown. Thus, EMI control and device safety are closely tied to design aims. This points to a clear need for snubber-based fixes.

RCD snubber capacitors reduce EMI by absorbing excess energy during switching transitions and preventing uncontrolled voltage rise. In an RCD snubber circuit, the capacitor captures energy from leakage inductance while the resistor dissipates this energy in a controlled manner. The diode ensures unidirectional operation, allowing the snubber to engage only during specific switching intervals.

This setup lets the Snubber Capacitor step in just when high dv/dt events hit. It clamps voltage overshoot. It also eases transient actions. As a result, the RCD setup stops parasitic oscillations from starting.

Snubber capacitors suppress EMI by limiting dv/dt and damping resonant oscillations at their origin. When properly selected, the capacitor reduces peak voltage and shortens ringing duration, significantly lowering high-frequency noise content. This suppression directly improves conducted and radiated EMI performance.

Unlike after-the-fact filters, RCD snubber capacitors work right at the switching point. This close-up effort limits noise spread through the system. It also cuts the need for large EMI filters.

RCD snubber capacitors deliver dual benefits by addressing EMI and improving device reliability simultaneously. By controlling voltage stress, the snubber reduces electrical fatigue on switching components, extending operational life. At the same time, smoother switching transitions result in lower electromagnetic emissions.

This two-way role makes snubber capacitors very useful in tight power-density setups. There, both the EMI room and the part lifespan face strict limits.

Capacitance value shapes how well an RCD snubber capacitor fights EMI. A capacitor too small might not take in enough energy. Then, leftover ringing lingers. On the other hand, too much capacitance can raise power loss. It also lowers efficiency.

Picking the voltage rating matters just as much. The capacitor must handle repeated transient strain without wear. An adequate voltage buffer keeps EMI steady over long runs and changing loads.

Equivalent series resistance (ESR) and equivalent series inductance (ESL) shape EMI control strongly. Low ESR allows good energy release. Low ESL lets the capacitor handle high-frequency transients well.

Pulse handling ability decides if the snubber capacitor can endure repeated surge currents from switching. Capacitors made for snubber uses must keep steady traits under ongoing high dv/dt strain.

Thermal stability proves vital for steady EMI results over time. High temperatures can change capacitance, ESR, and insulation resistance. This slowly weakens noise control.

Snubber capacitors in industrial and energy uses must give reliable work across broad temperature spans. Steady heat action ensures EMI control stays strong through the product life.

Flyback converters often face big voltage spikes from transformer leakage inductance. In these setups, RCD snubber capacitors go on the primary side. They clamp the voltage, strain, and cut the EMI output.

In real SMPS projects, well-set snubber capacitors steady switching waves. They also ease EMI compliance checks. Systems running non-stop under shifting loads gain a lot from this focused noise handling.

Inverters and DC-DC converters in renewable energy, EV charging, and industrial drives deal with steady EMI issues. High switching energy causes this. RCD snubber capacitors help by capping transient energy at key spots.

In motor drive uses, better EMI control also cuts interference with control electronics and feedback setups. Real-world installs with snubber capacitors note smoother runs and stronger system build.

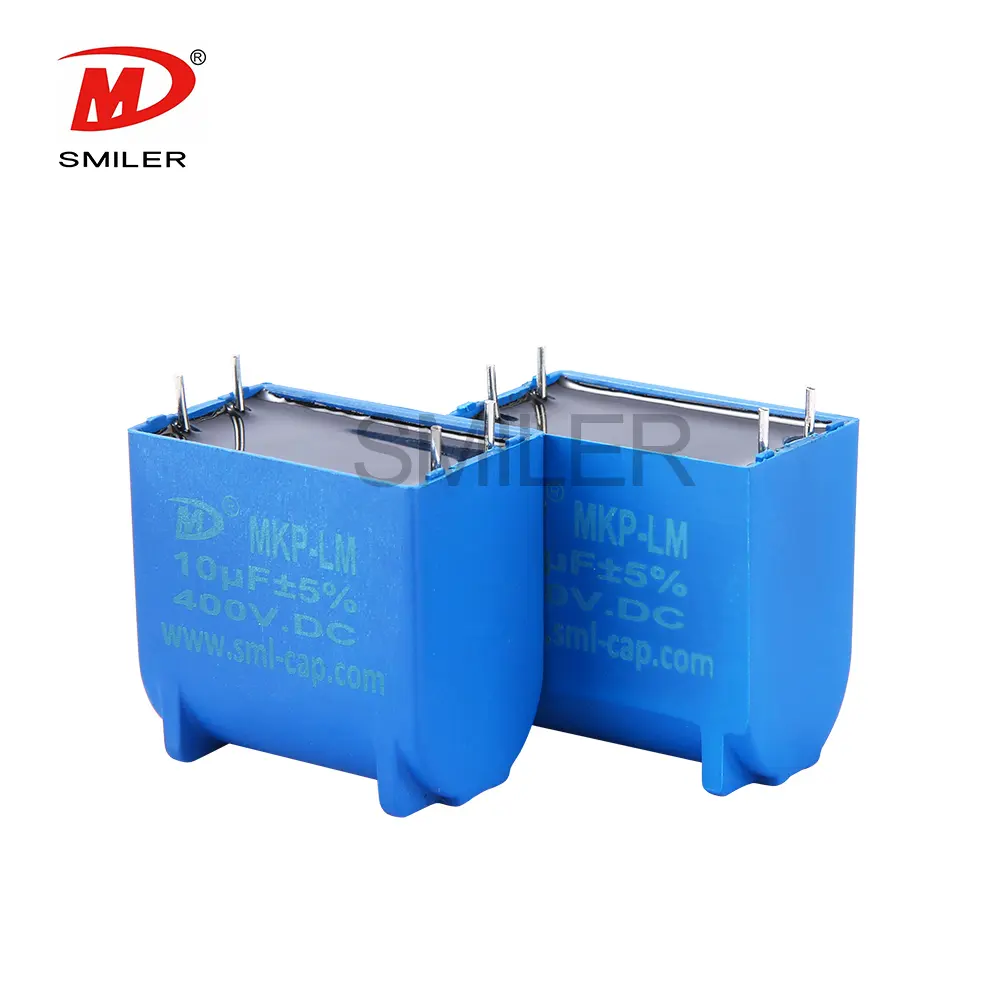

SMILER capacitor backs EMI-focused RCD snubber uses with special film capacitor builds. These fit high dv/dt and pulse strain. Made from metallized polypropylene film, these capacitors offer low ESR and managed inductance. This makes them right for tough snubber settings.

In projects with high-frequency power supplies and industrial converters, SMILER capacitor snubber items provide steady switching actions. They also lower EMI-caused breakdowns. By fitting capacitance values, voltage ratings, and build shapes, these fixes tackle exact issues from EMI checks.

SMILER capacitor skips generic parts. It focuses on matching driven by applications. This lets engineers fix voltage overshoot, ringing, and EMI issues spotted early in design. The result is systems that run well over long service times.

A: RCD snubber capacitors reduce EMI by clamping voltage overshoot, limiting dv/dt, and suppressing high-frequency ringing at the switching node. These actions lower conducted and radiated noise while also protecting power devices from electrical stress.

A: Selecting RCD snubber capacitors involves evaluating capacitance value, voltage rating, ESR, ESL, pulse current capability, and thermal stability. Matching these parameters to the actual switching conditions is essential for effective EMI suppression.

A: RCD snubber capacitors provide more controlled energy dissipation compared to RC snubbers, often resulting in improved EMI suppression and lower power loss. The optimal choice depends on topology, switching frequency, and efficiency targets.

A: For industrial power electronics requiring stable EMI performance, film capacitors designed specifically for snubber applications are commonly preferred. SMILER capacitor offers snubber solutions engineered for high dv/dt and long-term reliability.

A: RCD snubber capacitors are widely used in flyback power supplies, inverters, DC-DC converters, motor drives, and renewable energy systems where high-frequency switching and EMI control are critical to stable operation.

How Snubber Capacitor Impacts RC and RCD Snubber Performance

Analyzing DC Link Dynamics in Modern Electric Vehicles

DC Link Capacitor Design: A Comprehensive Selection Guide

Understanding Capacitor Filter Circuit: Frequency and Value Relationship

Choosing the Right Filter Capacitor for Induction Cooker: An In-Depth Guide